It's easy to use

“The training was so easy and on-point. I was comfortably running the machines inside a week! The software is very easy to use, and you just can’t put a price on the standard training they include”

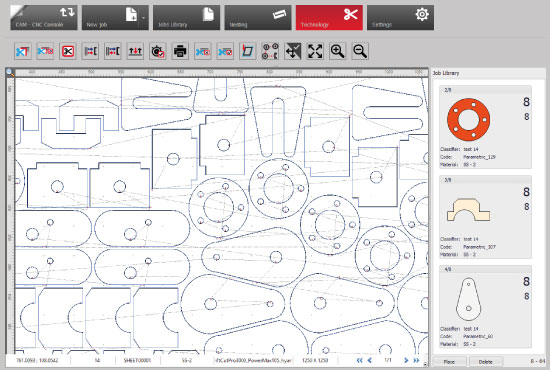

Import DXF, DWG, and JPEG file formats in just a few clicks. Alternatively use our 89-shape parametric library and skip the drawing part altogether!

Affordable, smart cutting

“The growth potential and productivity improvements mean that although I originally predicted an ROI of 3 years, now that I’ve seen what the Swift-Cut Pro can do, it’ll pay for itself in 6 months”

Our cutting machines are built to last, with relatively low running costs and basic service requirements. All this adds up to a speedy ROI.

See it in action

“As soon as we saw Swift-Cut, we knew we had found that machine”

We have dedicated experience centers in many locations around the world. We can also carry out personalised remote demonstrations over Zoom, TeamViewer, Microsoft Teams and WhatsApp platforms. You can send-in or bring parts or drawings with you to cut out, or we can create something for you which best represents your particular application.

Swift-Cut Pro Range Sizes

Benefits of a Swift-Cut Pro

There’s lots of reasons why the Swift-Cut Pro is the worlds best selling CNC plasma cutting machine. Here, we’ve summarised the top 12!

- Full online support worldwide

- Fully welded base

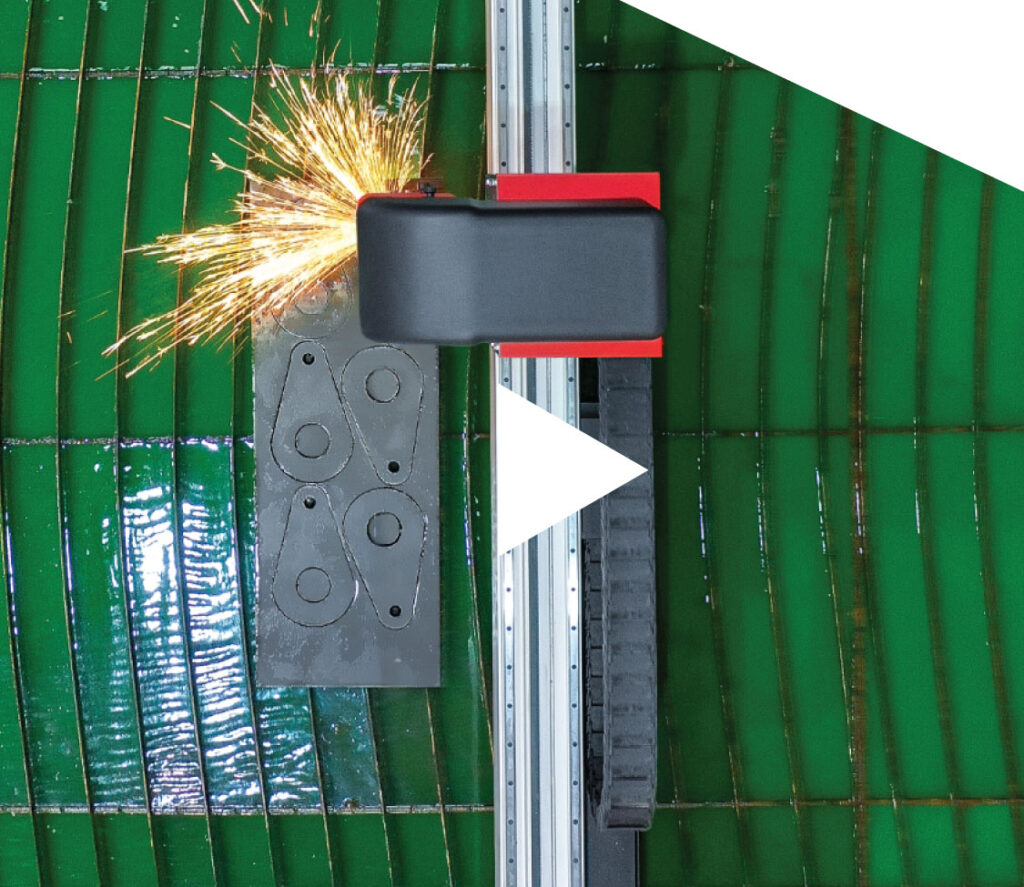

- 360-degree breakaway head

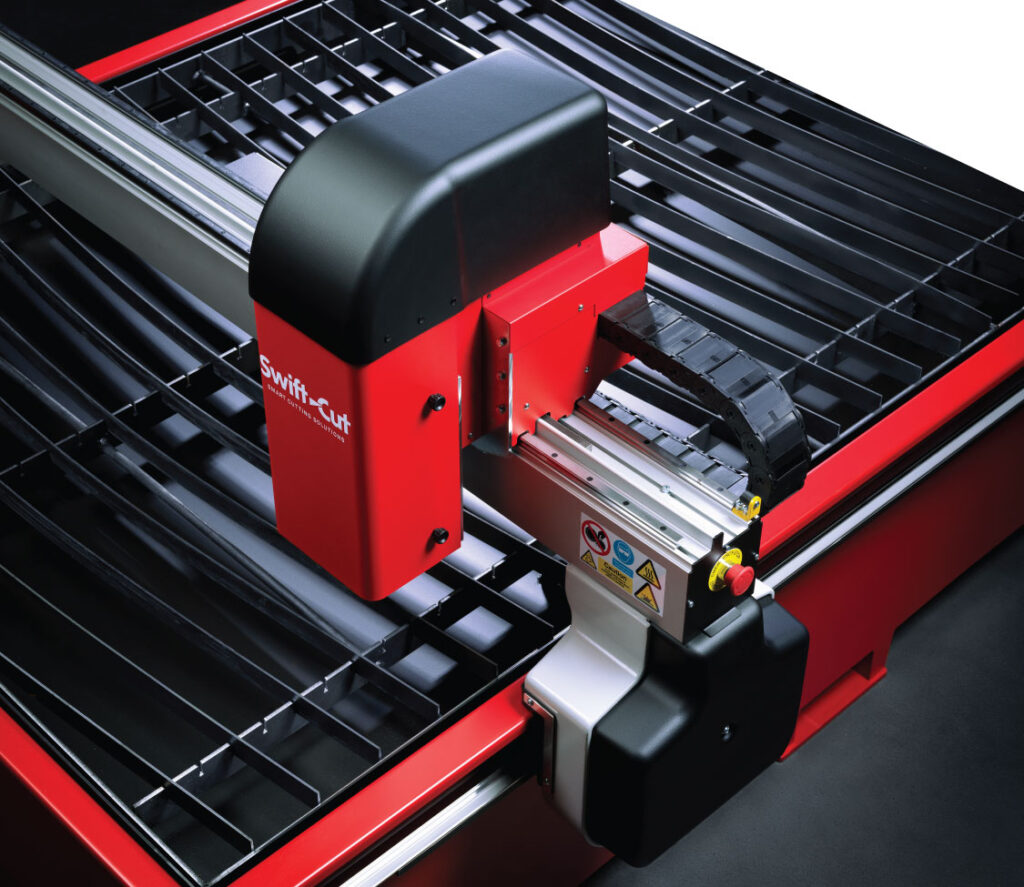

- Fully enclosed cutting head

- Heavy duty gantry and end castings

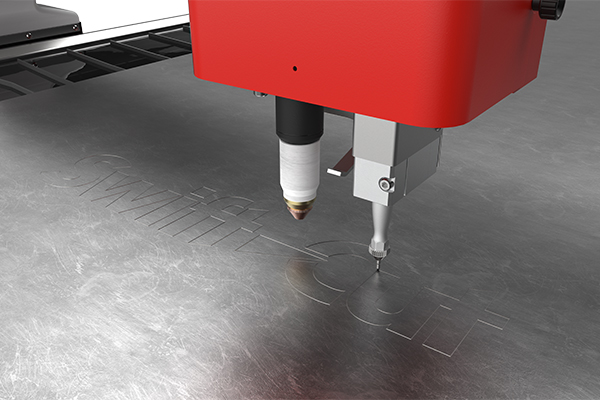

- SwiftMARK engraving tool (optional)

- Cut metal up to 1″ thick

- Standalone operators console

- Laser positioning crosshair

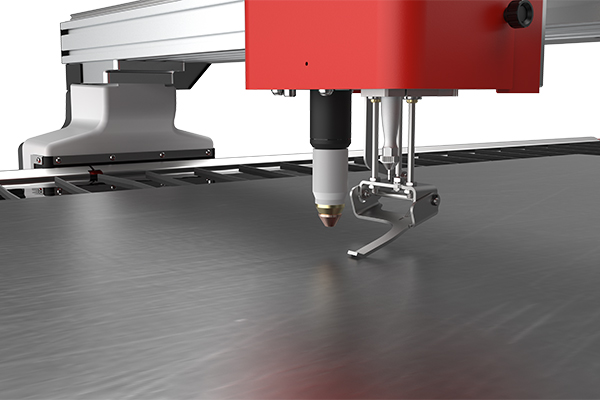

- Intelligent torch height control

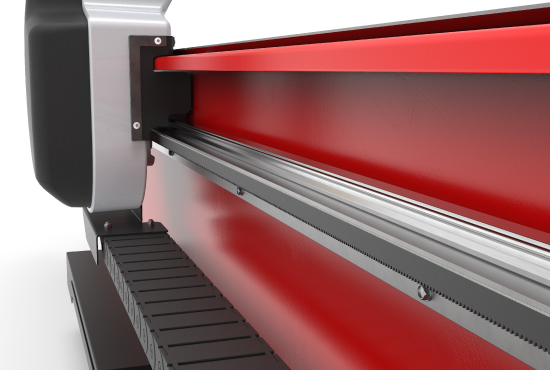

- Fully enclosed drag chains

- All sizes available in downdraft* or water table fume suppression (*except Pro 613)

- Full online support worldwide

- Fully welded base

- 360-degree breakaway head

- Fully enclosed cutting head

- Heavy duty gantry and end castings

- SwiftMARK engraving tool (optional)

- Cut metal up to 1″ thick

- Standalone operators console

- Laser positioning crosshair

- Intelligent torch height control

- Fully enclosed drag chains

- All sizes available in downdraft* or water table fume suppression (*except Pro 613)

We have outstanding feedback

We have outstanding feedback

“We have been totally blown away with the machine and it has exceeded all our expectations”

Andy Groves

Profab

“Swift-Cut are a great team to work with”

Charl Botha

Brits Plasma Cutting

Technical specification

Heavy duty gantry end castings with machined faces, together with the lightweight but rigid gantry, and fully welded base, provides a precise and stable platform for the cutting head.

Full suite of software included

From drawing, to nesting, to cutting, all Swift-Cut CNC machines include the necessary software to bring your ideas to life. The software is not subscription based so there’s no monthly fees.

Precision linear rail

Linear rail on all axes, including twin rail on the x-axis, ensures straight, accurate, and repeatable movements, plus a smoother motion compared to other guide systems.

Engraving head

The SwiftMARK engraving tool allows you to mark and cut in one operation, meaning no more outsourcing or moving project from one machine to another (optional extra).

Torch height control and Soft Sense

Intelligent Torch Height Control (ITHC) and Soft Sense initial height sense ensure the perfect pierce and cut height no matter what thickness of material being cut.

Operators console

Ergonomic operators console with touch screen and keyboard/mouse inputs. The console can be placed on either side of the machine.

All technical information and more is now available in our brochures.

To get access to all of our documentation you will need to complete this form.

Powermax45xp – Cut up to 1/2″

Powermax65 SYNC™ – Cut up to 5/8″

Powermax85 SYNC™ – Cut up to 3/4″

Powermax105 SYNC™ – Cut up to 7/8″

Powermax125 – Cut up to 1″

ESAB A120 – Cut up to ¾”

Swift-Cut is the world’s first light industrial CNC OEM to fully test and integrate the new Hypertherm Powermax SYNC™ plasma systems with our cutting machines and software

Our tech specs are now available in our brochures.

Please complete this short form to gain full access

Take control of your cutting with a Swift-Cut CNC machine

Whether you’re ready to buy, would like a demonstration in our customer experience centre, or just have some questions regarding our machines or software, please feel free to leave an enquiry and one of our team will be in touch.

- Easy to use & Affordable

- Heavy-duty design & Proven reliability

- Fantastic support

- Superb cut quality

- Quick setup & Feature rich

See other Swift-Cut products

A collection of cutting-edge CNC plasma and waterjet cutting machines. Whether you want to plasma cut 26 gauge galvanised mild steel, or waterjet 4” expanded foam, we have the CNC cutting machine for you.

See other Swift-Cut Products

A collection of cutting-edge CNC plasma and waterjet cutting machines. Whether you want to plasma cut 26 gauge galvanised mild steel, or waterjet 4” expanded foam, we have the CNC cutting machine for you.

FAQ's

FAQ’s

Do I need a downdraft (DD) or water table (WT) machine to capture fumes?

It all depends on your particular application. Downdraft tables are slightly more expensive to purchase than water tables and require connection to either a filtration unit or extraction fan. The additional equipment adds extra noise, but they are easier to clean and your only option if cutting aluminium and stainless steel most of the time. Water tables are less expensive and quieter, and do not require any additional hardware, however they are more difficult to clean and not recommended for certain materials.

What plasma power source is right for me?

There are six plasma power sources to choose from when looking at the Pro range. The main difference between each power source is the cutting capacity (generally quoted as the maximum pierce thickness). The options are up to 1/2″, up to 5/8″, up to 3/4″ , up to 7/8″, up to 1″, and up to 1 1/4″. As a rule of thumb, you should always choose the power source that will comfortably cut your most common thicknesses, so for example if you cut 5/8″ plate most days, you would want to go for the 3/4″ capacity power source. Alternatively, if you cut 5/8″ infrequently and mostly cut 1/2″, then the 5/8″ capacity power source might be better suited.

How much are they?

Please click on our pricing page for information on general pricing for each of our CNC machines. Alternatively, please leave your details on the contact form, or drop us a call or email, and one of our Sales team will be in touch to discuss your particular application(s) in more detail. This will allow us to create a bespoke quotation which includes all the things you need, and non of the things you don’t.

What do I need to run one?

Our Pro series CNC plasma machines require an electricity supply and compressed air supply in order to run. The table (inc. console) requires a single phase 110v-230v (6A-4A) electricity supply. The plasma power source will require a single phase 230v (32A) up to a three phase 415v (64A) electricity supply, depending on the model chosen. The compressed air supply will need to be clean and free of moisture, oil, and any other contaminants. The compressor will need to deliver 17CFM of air flow and have a holding pressure of 7.5bar (110psi).