Next level cutting

“The XP machine is one of the best purchases we’ve ever made. It’s everything we could have hoped for”

The brief was simple, take all that we learnt with our best-selling Swift-Cut Pro plasma machine and build it bigger, stronger and more powerful than ever before.

High performance

“The XP is a good, solid machine that is reliable and efficient. It saves us at least 40 hours a week”

AC Servo motors, helical rack and plasma power source options up to 1.25” capacity, the XP range is a feature rich, production ready system that maintains the ease of use and value that all Swift-Cut tables are synonymous with

See it in action

“As soon as we saw the Swift-Cut XP, we knew we had found that machine”

We have dedicated experience centers in many locations around the world. We can also carry out personalised remote demonstrations over Zoom, TeamViewer, Microsoft Teams and WhatsApp platforms. You can send-in or bring parts or drawings with you to cut out, or we can create something for you which best represents your application.

Benefits of a Swift-Cut XP

There’s lots of reasons why the Swift-Cut XP leads the way in durability, affordability, and features. Here, we’ve summarised the top 12!

- Full online support worldwide

- Super heavy-duty fully welded base

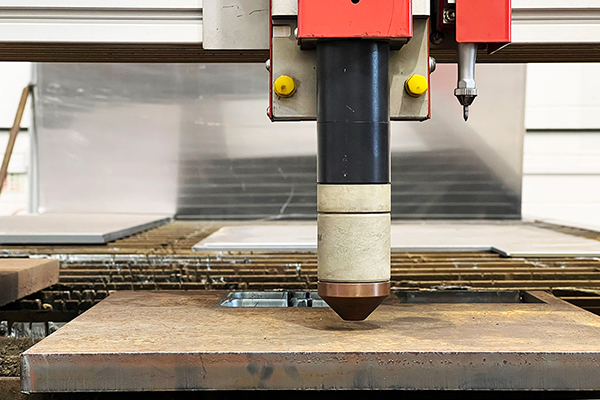

- 360-degree breakaway head

- Cut up to 8” box section

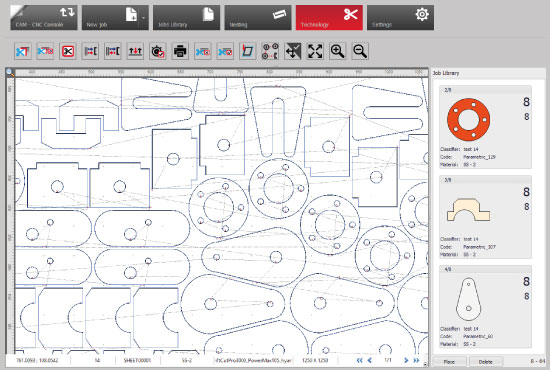

- Advanced CAM software with auto nest as standard

- SwiftMARK engraving tool

- Cut metal up to 1.25” thick

- Standalone operators console

- Intelligent torch height control

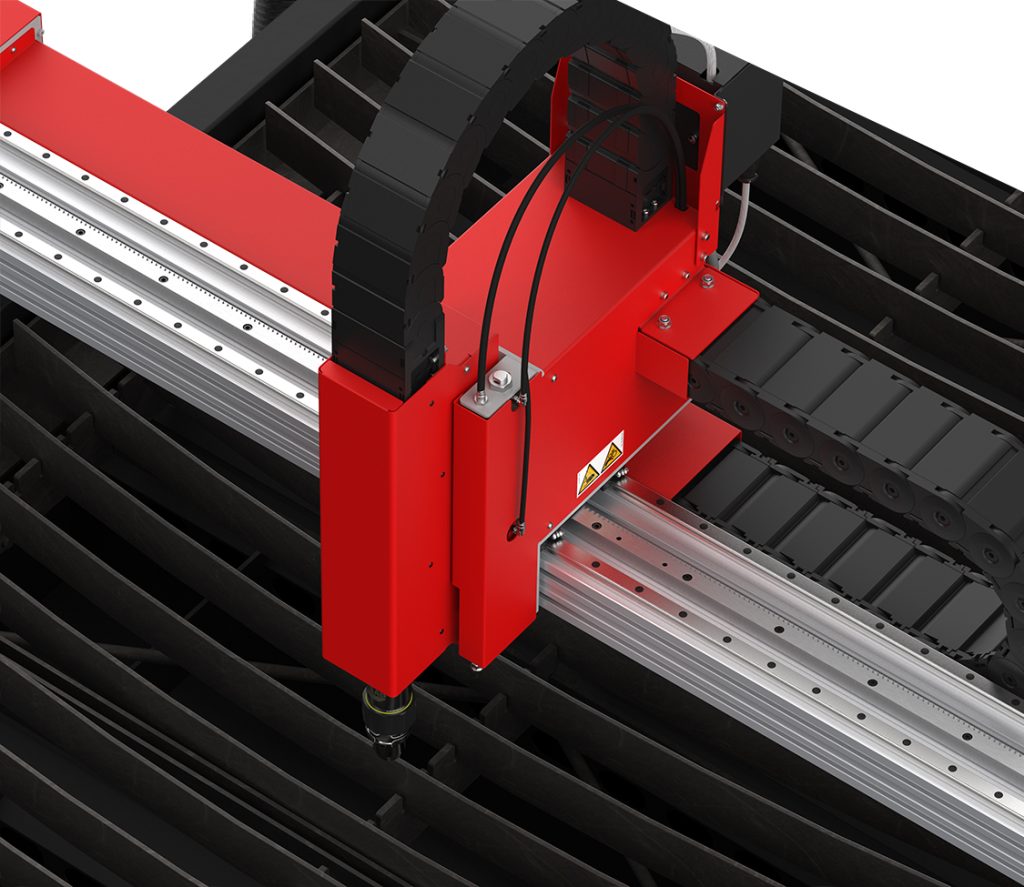

- Fully enclosed drag chains

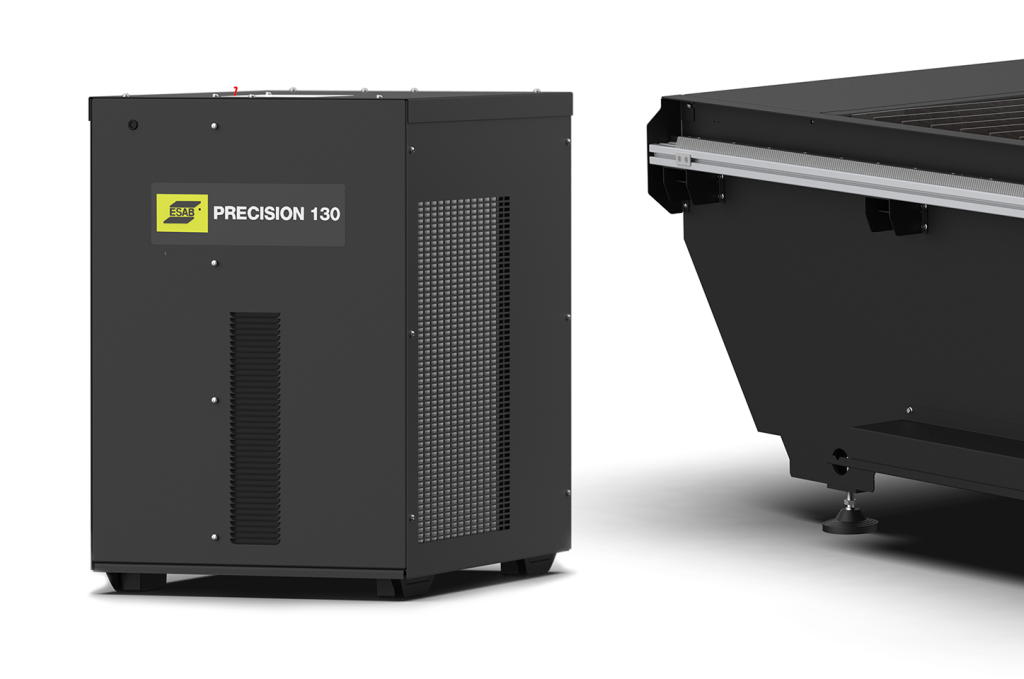

- 8 plasma power source options, inc. mixed gas cutting and water mist secondary

- Smooth & powerful AC Servo motors on all axes

- Full online support worldwide

- Super heavy-duty fully welded base

- 360-degree breakaway head

- Cut up to 8” box section

- Advanced CAM software with auto nest as standard

- SwiftMARK engraving tool

- Cut metal up to 1.25” thick

- Standalone operators console

- Intelligent torch height control

- Fully enclosed drag chains

- 8 plasma power source options, inc. mixed gas cutting and water mist secondary

- Smooth & powerful AC Servo motors on all axes

We have outstanding feedback

We have outstanding feedback

“The XP machine is one of the best purchases we’ve ever made. It’s everything we could have hoped for”

Pete Harry

ML Ruberton Construction

“As soon as we saw the Swift-Cut XP, we knew we had found that machine”

Matt Logan

LLIW

Take control of your cutting with a Swift-Cut CNC machine

Whether you’re ready to buy, would like a demonstration in our customer experience centre, or just have some questions regarding our machines or software, please feel free to leave an enquiry and one of our team will be in touch.

- Easy to use & Affordable

- Heavy-duty design & Proven reliability

- Fantastic support

- Superb cut quality

- Quick setup & Feature rich

Technical specification

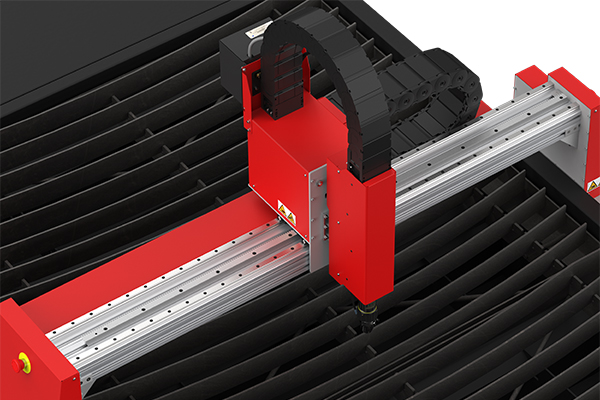

Super heavy-duty gantry and base

Reinforced aluminium extrusion gantry with machined end castings and steel protection covers, combined with an all-steel construction fully welded base, means you have the foundation to cut thick metal plate, day in and day out

Full suite of software included

From drawing, to nesting, to cutting, all Swift-Cut CNC machines include the necessary software to bring your ideas to life. The software is not subscription based so there’s no monthly fees. The XP package also comes with auto nesting software as standard, so maximum sheet utilisation is just a click away

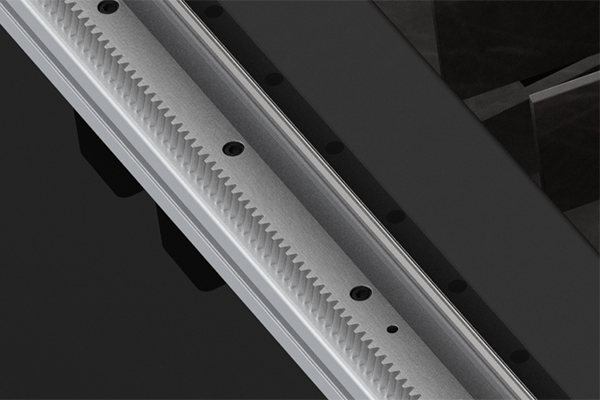

Precision linear rail & helical rack

Linear rail and helical rack on all axes, including twin rail on the x-axis, ensures straight, accurate, and repeatable movements, plus powerful AC servo motors provide a superior motion compared to other guide systems

Engraving head

The SwiftMARK engraving tool allows you to mark and cut in one operation, meaning no more outsourcing or moving project from one machine to another (optional extra).

Torch height control

Intelligent Torch Height Control (ITHC) and Floating initial height sense ensure accurate pierce and cut heights on a wide range of material thicknesses

Mixed gas cutting

Specify the XP machine with a Hypertherm MAXPRO200 or ESAB m2 200i power source, and enjoy the benefits of 200 amps of cutting power. Cut up to 1 ¼” with mixed cutting gas options for improved edge finish, faster cut speeds, less dross, less taper and longer consumable life

All technical information and more is now available in our brochures.

To get access to all of our documentation you will need to complete this form.

Powermax105 SYNC™ – Up to 22mm

Powermax125 – Up to 25mm

MAXPRO200 – Up to 32mm

Auto-cut 300

Our tech specs are now available in our brochures.

Please complete this short form to gain full access

See other Swift-Cut products

A collection of cutting-edge CNC plasma and waterjet cutting machines. Whether you want to plasma cut 26 gauge galvanised mild steel, or waterjet 4” expanded foam, we have the CNC cutting machine for you.

See other Swift-Cut Products

A collection of cutting-edge CNC plasma and waterjet cutting machines. Whether you want to plasma cut 26 gauge galvanised mild steel, or waterjet 4” expanded foam, we have the CNC cutting machine for you.

FAQ's

FAQ’s

It all depends on your particular application. Downdraft tables are slightly more expensive to purchase than water tables and require connection to either a filtration unit or extraction fan. The additional equipment adds extra noise, but they are easier to clean and your only option if cutting aluminium and stainless steel most of the time. Water tables are less expensive and quieter, and do not require any additional hardware, however they are more difficult to clean and not recommended for certain materials.

Please click on our pricing page for information on general pricing for each of our CNC machines. Alternatively, please leave your details on the contact form, or drop us a call or email, and one of our Sales team will be in touch to discuss your particular application(s) in more detail. This will allow us to create a bespoke quotation which includes all the things you need, and none of the things you don’t.