“We use the machine every day and would be LOST without it!”

Ward Fabrication is a family-run business with an impressive drive to maintain their reputation for providing customers with technical knowledge, expertise and a quality service – something they have been doing since 1994, although their story actually started back in the sixties.

They take time to choose the right equipment; it’s not simply the spec of the build that needs to impress, but the company behind the machinery must share their ethos for customer care. When they chose Swift-Cut to replace their current CNC table, they recognized the desire to provide more than the average, and they knew that they had found a company that they could work well with.

No strangers to plasma, they had built their previous machine from scratch back in 2010 and implemented a software “kit” to run the machine. They used that machine daily for eleven years, cutting a plethora of materials for a huge number of custom projects. While their original machine allowed them to switch from outsourcing to in-house, they had a steep learning curve with the kit software, finding it clunky to move files around and create the proper layout on the sheets.

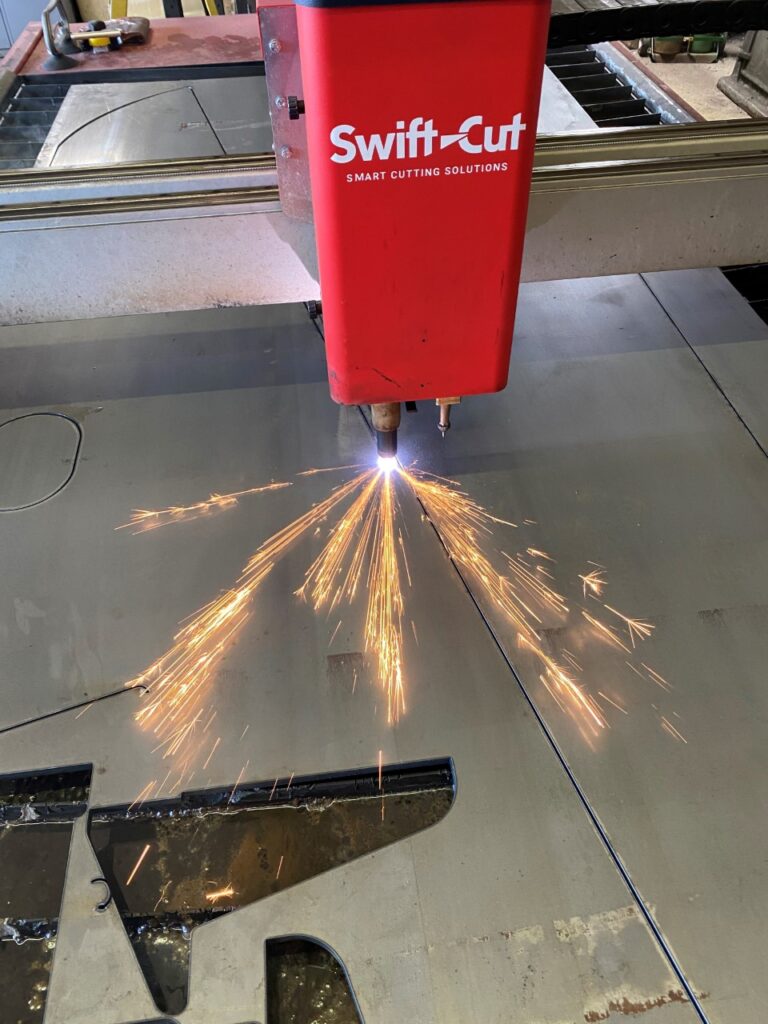

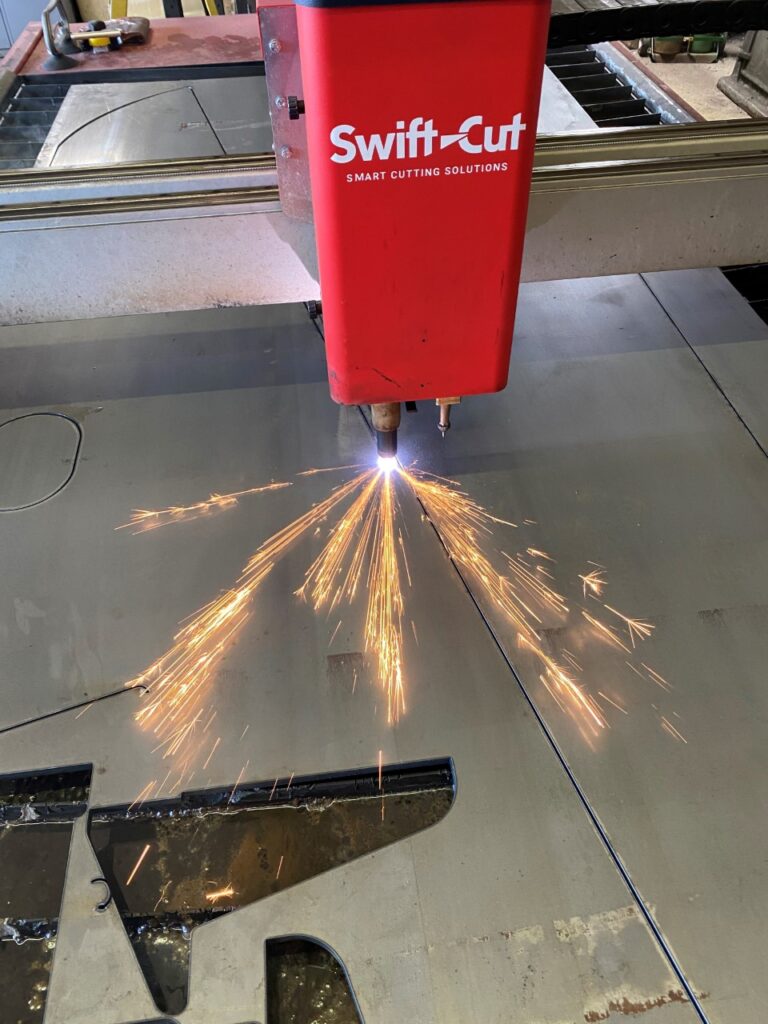

They knew that they needed to upgrade, and so they chose a Swift-Cut Pro 510 water table, with a Swift-Mark engraver, auto nesting software and Hypertherm Powermax 85 – it’s safe to say, they haven’t looked back.

Their table arrived over the weekend to minimize downtime, with the team at Ward completing some simple tasks to set it up. A few minor tweaks to adjust the head and torch from the Swift-Cut technician, and the table was up and running, cutting parts within two hours.

And it’s no stretch to say that the simple to use software has been a welcome and necessary change for them.

Kelly Ward, president of Ward Fabrication, said “The software is very simple to use. As with anything, there is some learning to do, but once you see the way it works, it’s far more simple than a lot of the CNC software out there in the market. We find ourselves still surprised that we’re “ready to cut” so fast compared to the other CNC machines we have.”

Ward Fabrication is a custom fabrication business; cutting steel, stainless steel and aluminium on a regular basis however sometimes have some personalized requests using customer-provided materials, such as AR500 plate. They also have some products that are made in a production style run which can take up the whole table for multiple sheets, while other jobs they use different thickness materials all nested on the table together. They needed a machine that was robust enough to be able to keep up with the demand of their regular work but also instinctive and adaptable, to enable a better degree of flexibility. They found that in Swift-Cut.

“The capabilities of this machine allow us to be extremely versatile, and in today’s world, that is a necessary ability!” Kelly added, “our Swift-Cut has become our “go-to” machine when we need a template, brace, or any type of fixture style part. The quality and accuracy of the cuts are reliable, we can bank on the fact that the parts will come out right and that matters to our team!”

And they have found the support from Swift-Cut exceptional, “I personally love how the technician can log in through the team viewer and show us on the screen what to do. Just the other day we had a small issue, we called and the tech was able to jump right in and fix the problem within minutes!”

They use the table five days a week, sometimes six. “It’s on and running by 7:30am and we shut it down around 5:00pm. Some days we are cutting non-stop all day and some days we are working on a design so we need to cut some then do test fits and then change the parts up a bit. All in all, we use the machine every day and would be LOST without it!”

We wanted to know if they could gauge whether the addition of the Swift-Cut had saved them money, not something that necessarily we take as a given when it’s replacing another CNC plasma table. However they said that the amount of time saved by the speed of the software, as well as the ability to place material wherever, and cut straight away, is amazing.

“We are a small shop in comparison to most around us, but we shine with regard to speed and quality. I started this company in 1994, and it has grown minimally in personnel size but we have exploded in customer base, due to our ability to produce custom shaped parts that help our customers realize their ideas and projects. The Swift-Cut table has leap frogged us past our competition by allowing us to produce our fabrication with a custom flair that keeps us on top!”

It’s been so successful in fact, that after only a year of having their table, the machine has already paid for itself – it’s the kind of ROI that we’re used to hearing here at Swift-Cut, but it never loses its thrill for us.

“We are constantly striving to improve our speed without the compromise to quality. The Swift-Cut machine has been a huge help in that respect!”

And excitingly, an opportunity to develop a new product recently arose (one that has now been added to their list of patented products) which was made easier and more efficient thanks to their Swift-Cut table.

“Every customer that sees our setup is impressed with the machine and its performance, so that’s a great thing for both of us!” You’re right, we couldn’t be happier to be part of your success story, Ward Fabrication!

Ward Fabrication is a family-run business with an impressive drive to maintain their reputation for providing customers with technical knowledge, expertise and a quality service – something they have been doing since 1994, although their story actually started back in the sixties.

They take time to choose the right equipment; it’s not simply the spec of the build that needs to impress, but the company behind the machinery must share their ethos for customer care. When they chose Swift-Cut to replace their current CNC table, they recognized the desire to provide more than the average, and they knew that they had found a company that they could work well with.

No strangers to plasma, they had built their previous machine from scratch back in 2010 and implemented a software “kit” to run the machine. They used that machine daily for eleven years, cutting a plethora of materials for a huge number of custom projects. While their original machine allowed them to switch from outsourcing to in-house, they had a steep learning curve with the kit software, finding it clunky to move files around and create the proper layout on the sheets.

They knew that they needed to upgrade, and so they chose a Swift-Cut Pro 510 water table, with a Swift-Mark engraver, auto nesting software and Hypertherm Powermax 85 – it’s safe to say, they haven’t looked back.

Their table arrived over the weekend to minimize downtime, with the team at Ward completing some simple tasks to set it up. A few minor tweaks to adjust the head and torch from the Swift-Cut technician, and the table was up and running, cutting parts within two hours.

And it’s no stretch to say that the simple to use software has been a welcome and necessary change for them.

Kelly Ward, president of Ward Fabrication, said “The software is very simple to use. As with anything, there is some learning to do, but once you see the way it works, it’s far more simple than a lot of the CNC software out there in the market. We find ourselves still surprised that we’re “ready to cut” so fast compared to the other CNC machines we have.”

Ward Fabrication is a custom fabrication business; cutting steel, stainless steel and aluminium on a regular basis however sometimes have some personalized requests using customer-provided materials, such as AR500 plate. They also have some products that are made in a production style run which can take up the whole table for multiple sheets, while other jobs they use different thickness materials all nested on the table together. They needed a machine that was robust enough to be able to keep up with the demand of their regular work but also instinctive and adaptable, to enable a better degree of flexibility. They found that in Swift-Cut.

“The capabilities of this machine allow us to be extremely versatile, and in today’s world, that is a necessary ability!” Kelly added, “our Swift-Cut has become our “go-to” machine when we need a template, brace, or any type of fixture style part. The quality and accuracy of the cuts are reliable, we can bank on the fact that the parts will come out right and that matters to our team!”

And they have found the support from Swift-Cut exceptional, “I personally love how the technician can log in through the team viewer and show us on the screen what to do. Just the other day we had a small issue, we called and the tech was able to jump right in and fix the problem within minutes!”

They use the table five days a week, sometimes six. “It’s on and running by 7:30am and we shut it down around 5:00pm. Some days we are cutting non-stop all day and some days we are working on a design so we need to cut some then do test fits and then change the parts up a bit. All in all, we use the machine every day and would be LOST without it!”

We wanted to know if they could gauge whether the addition of the Swift-Cut had saved them money, not something that necessarily we take as a given when it’s replacing another CNC plasma table. However they said that the amount of time saved by the speed of the software, as well as the ability to place material wherever, and cut straight away, is amazing.

“We are a small shop in comparison to most around us, but we shine with regard to speed and quality. I started this company in 1994, and it has grown minimally in personnel size but we have exploded in customer base, due to our ability to produce custom shaped parts that help our customers realize their ideas and projects. The Swift-Cut table has leap frogged us past our competition by allowing us to produce our fabrication with a custom flair that keeps us on top!”

It’s been so successful in fact, that after only a year of having their table, the machine has already paid for itself – it’s the kind of ROI that we’re used to hearing here at Swift-Cut, but it never loses its thrill for us.

“We are constantly striving to improve our speed without the compromise to quality. The Swift-Cut machine has been a huge help in that respect!”

And excitingly, an opportunity to develop a new product recently arose (one that has now been added to their list of patented products) which was made easier and more efficient thanks to their Swift-Cut table.

“Every customer that sees our setup is impressed with the machine and its performance, so that’s a great thing for both of us!” You’re right, we couldn’t be happier to be part of your success story, Ward Fabrication!