Metal Supermarkets Franchise Adds Value by Adding Swift-Cut XP CNC Plasma Cutting Table

In the world of small quantity metals suppliers, Metal Supermarkets looms large with its network of more than one hundred and twenty franchise locations across the U.S. and Canada. The company is structured to provide customers “any metal, any size, cut and ready fast.” For Baltimore franchise owner Henry Dow, adding an automated plasma cutting system enabled him to better serve customers while benefiting his bottom line.

“As soon as we added the Swift-Cut 10 x 5ft plasma table, the improvement in our turnaround was tremendous,” says Dow. “To start, we do not need to rely on vendors to create a part design. With the Swift-Cut software, which has a built-in parts shape library, we can design and cut something on the same day or the next day in most cases. Even if it’s a complex design, the speed difference is night and day.”

The Swift-Cut XP is an affordable CNC plasma cutting machine that delivers precise high-speed air-plasma cutting of metal up to 1 inch thick. Unlike a shear or saw, the plasma cutter enables cutting shapes and holes, plus it enables cutting thicker metal.

Incorporating a CNC plasma cutter has helped Metal Supermarkets generate more, as well as repeat, business. When Dow bought the franchise in 2011, sales were under $1 million. Now, his latest annual sales have reached $6 million.

“There were sixty franchise locations when we started, and we weren’t even in the top fifteen,” says Dow. “Now it’s one hundred and twent stores, and we’re number one.”

“I was one of the first to gravitate toward added services, such as cutting shapes and holes and bending, and now other stores are doing the same because they see the benefits,” he says.

Breaking Down the Benefits

Giving a customer exactly what they need sometimes requires give and take. For example, some fabricators who bought steel from other sources became customers when cutting material themselves took too long.

“We have had people stop their job and deliver material to us to cut to shape,” says Dow. “It raised their material costs a bit, but it lowered their overall cost because they were able to complete the project faster and move on to the next one.”

Normally, Metal Supermarkets won’t cut steel purchased from other sources, but there are exceptions.

“We’re willing to accommodate a new customer to get them out of a bind,” says Dow. “After that first time, they understand it is a waste of time trying to find the cheapest supplier when we can deliver an immediate solution.”

To demonstrate the benefits of working with Metal Supermarkets, Dow outlines a couple of hypothetical scenarios.

“If you have a 32-sq.-ft. sheet of metal, and say it’s $5/sq. ft., but you only need a five 12- x 12-in plates, buying the whole plate generates a lot of waste — think of all the partial plates and skeletons stacked occupying space in the typical fab shop,” says Dow. “If I supply the plate, you may pay $6 or $7/sq. ft., but that’s all you’re getting. The material is ready to use. You don’t have to pay to cut it or store it.”

There are plenty of cases where Dow will quote customers multiple ways for the same job, and the customer’s cost of labor is often a large deciding factor.

“If someone needs two pieces at 30 in. or five pieces at 12 x 12 in., we’ll quote them for the sheet and for just the cut pieces. They almost always end up buying only what they need,” says Dow. “It just makes better sense to pay our labor rates for a saw tech or plasma table operator compared to paying a skilled welder out in the field to cut material using a torch or manual plasma cutter. Plus, when we cut it, the fabricator gets a cut clean with minimal edge prep, so our parts help speed fabrication time.”

Reliability

The Swift-Cut XP features a heavy-duty build with a base that is fully welded for strength and rigidity. The gantry is a custom aluminium extrusion with substantial machined end castings and powerful dual drive motors. Precision linear rails on all axes deliver straight, accurate and repeatable movement, while “Soft Sense” height sensing technology and intelligent torch height control provide cut consistency and extend consumables life.

When initially looking to automate cutting, Dow tried to cut corners, so to speak. “Before I bought the Swift-Cut, I was cheap and bought a very inexpensive table,” says Dow. “I called it a rich man’s garage toy, because it was for someone’s garage and not for industrial use. We beat it up so badly that it wouldn’t run correctly.”

Dow bought the Swift-Cut about five years ago and hasn’t looked back. “The Swift-Cut runs all day long. I could put it on a second shift if needed,” says Dow. “It’s a solid machine.”

Integrated Operation

After acquiring the plasma table, Dow recognized that he could now integrate additional equipment, such as a Primeline 350-ton hydraulic press brake.

“The only way we obtain the desired utilization rates for our press brake is by having the plasma table to feed it,” says Dow. “The combination of the two products is a big investment, but it’s also a productive combination — think of all the clips used in structural steel fabrication. They need bolt holes and a 90-degree angle, and that’s just what the plasma cutter/press brake combination gives us.”

It also gives him additional capabilities, typified by end pieces, to protect warehouse racking units owned by a shipping company. Due to forklift damage, the customer needed end plates to protect the racks. Previously, the shipping company used to buy regular angle, miter the angle, drill the holes in the angles and weld plates together. Fabricating this product was a real shop-stopper because it wasn’t their big thing. It would take them three or four weeks to fabricate a batch.

Dow figured out how to use the plasma cutter and press brake to fabricate the end pieces, and now a typical batch takes two to three days. The company has shipped these parts to Canada, Washington State, Colorado and Georgia. So anytime new shipping facility go up, the customer asks Metal Supermarkets to supply the end plates.

“What we’ve done is to think systematically, not in terms of one capability,” says Dow. “We want to add value, and you need to look at more than one operation at a time. Once you understand what your customers are looking for, you can see a whole value stream where you can contribute.”

In the world of small quantity metals suppliers, Metal Supermarkets looms large with its network of more than one hundred and twenty franchise locations across the U.S. and Canada. The company is structured to provide customers “any metal, any size, cut and ready fast.” For Baltimore franchise owner Henry Dow, adding an automated plasma cutting system enabled him to better serve customers while benefiting his bottom line.

“As soon as we added the Swift-Cut 10 x 5ft plasma table, the improvement in our turnaround was tremendous,” says Dow. “To start, we do not need to rely on vendors to create a part design. With the Swift-Cut software, which has a built-in parts shape library, we can design and cut something on the same day or the next day in most cases. Even if it’s a complex design, the speed difference is night and day.”

The Swift-Cut XP is an affordable CNC plasma cutting machine that delivers precise high-speed air-plasma cutting of metal up to 1 inch thick. Unlike a shear or saw, the plasma cutter enables cutting shapes and holes, plus it enables cutting thicker metal.

Incorporating a CNC plasma cutter has helped Metal Supermarkets generate more, as well as repeat, business. When Dow bought the franchise in 2011, sales were under $1 million. Now, his latest annual sales have reached $6 million.

“There were sixty franchise locations when we started, and we weren’t even in the top fifteen,” says Dow. “Now it’s one hundred and twent stores, and we’re number one.”

“I was one of the first to gravitate toward added services, such as cutting shapes and holes and bending, and now other stores are doing the same because they see the benefits,” he says.

Breaking Down the Benefits

Giving a customer exactly what they need sometimes requires give and take. For example, some fabricators who bought steel from other sources became customers when cutting material themselves took too long.

“We have had people stop their job and deliver material to us to cut to shape,” says Dow. “It raised their material costs a bit, but it lowered their overall cost because they were able to complete the project faster and move on to the next one.”

Normally, Metal Supermarkets won’t cut steel purchased from other sources, but there are exceptions.

“We’re willing to accommodate a new customer to get them out of a bind,” says Dow. “After that first time, they understand it is a waste of time trying to find the cheapest supplier when we can deliver an immediate solution.”

To demonstrate the benefits of working with Metal Supermarkets, Dow outlines a couple of hypothetical scenarios.

“If you have a 32-sq.-ft. sheet of metal, and say it’s $5/sq. ft., but you only need a five 12- x 12-in plates, buying the whole plate generates a lot of waste — think of all the partial plates and skeletons stacked occupying space in the typical fab shop,” says Dow. “If I supply the plate, you may pay $6 or $7/sq. ft., but that’s all you’re getting. The material is ready to use. You don’t have to pay to cut it or store it.”

There are plenty of cases where Dow will quote customers multiple ways for the same job, and the customer’s cost of labor is often a large deciding factor.

“If someone needs two pieces at 30 in. or five pieces at 12 x 12 in., we’ll quote them for the sheet and for just the cut pieces. They almost always end up buying only what they need,” says Dow. “It just makes better sense to pay our labor rates for a saw tech or plasma table operator compared to paying a skilled welder out in the field to cut material using a torch or manual plasma cutter. Plus, when we cut it, the fabricator gets a cut clean with minimal edge prep, so our parts help speed fabrication time.”

Reliability

The Swift-Cut XP features a heavy-duty build with a base that is fully welded for strength and rigidity. The gantry is a custom aluminium extrusion with substantial machined end castings and powerful dual drive motors. Precision linear rails on all axes deliver straight, accurate and repeatable movement, while “Soft Sense” height sensing technology and intelligent torch height control provide cut consistency and extend consumables life.

When initially looking to automate cutting, Dow tried to cut corners, so to speak. “Before I bought the Swift-Cut, I was cheap and bought a very inexpensive table,” says Dow. “I called it a rich man’s garage toy, because it was for someone’s garage and not for industrial use. We beat it up so badly that it wouldn’t run correctly.”

Dow bought the Swift-Cut about five years ago and hasn’t looked back. “The Swift-Cut runs all day long. I could put it on a second shift if needed,” says Dow. “It’s a solid machine.”

Integrated Operation

After acquiring the plasma table, Dow recognized that he could now integrate additional equipment, such as a Primeline 350-ton hydraulic press brake.

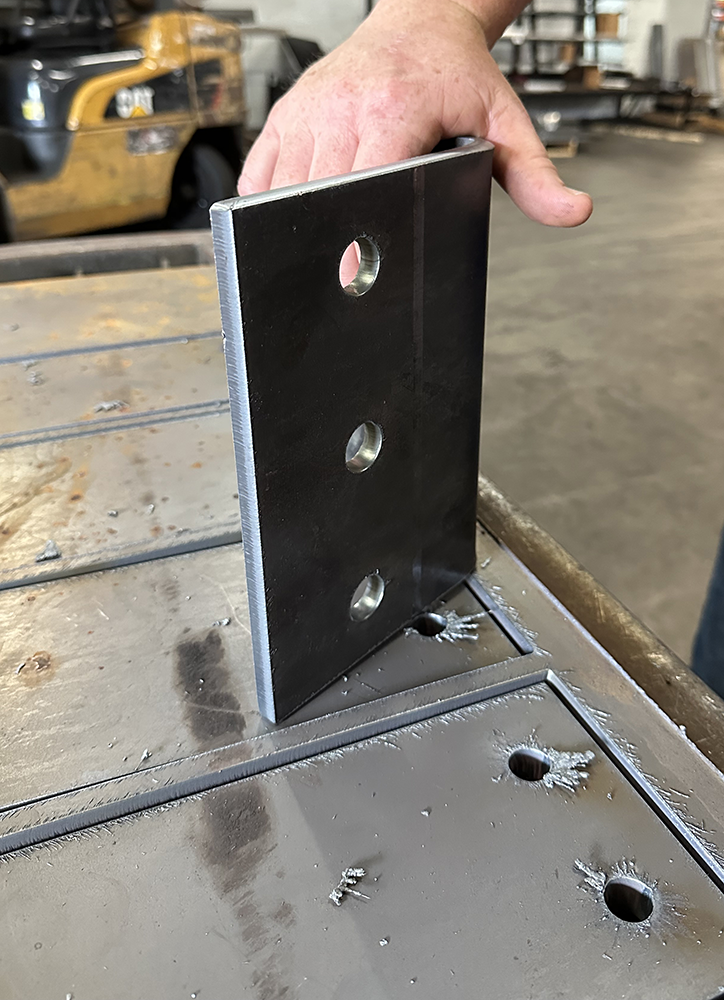

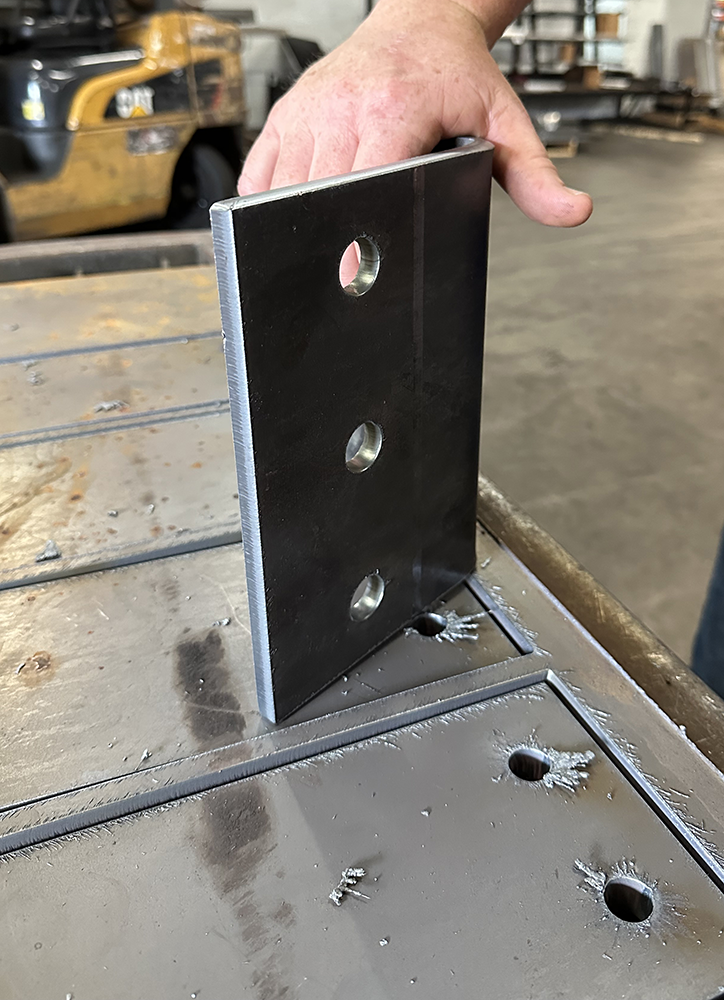

“The only way we obtain the desired utilization rates for our press brake is by having the plasma table to feed it,” says Dow. “The combination of the two products is a big investment, but it’s also a productive combination — think of all the clips used in structural steel fabrication. They need bolt holes and a 90-degree angle, and that’s just what the plasma cutter/press brake combination gives us.”

It also gives him additional capabilities, typified by end pieces, to protect warehouse racking units owned by a shipping company. Due to forklift damage, the customer needed end plates to protect the racks. Previously, the shipping company used to buy regular angle, miter the angle, drill the holes in the angles and weld plates together. Fabricating this product was a real shop-stopper because it wasn’t their big thing. It would take them three or four weeks to fabricate a batch.

Dow figured out how to use the plasma cutter and press brake to fabricate the end pieces, and now a typical batch takes two to three days. The company has shipped these parts to Canada, Washington State, Colorado and Georgia. So anytime new shipping facility go up, the customer asks Metal Supermarkets to supply the end plates.

“What we’ve done is to think systematically, not in terms of one capability,” says Dow. “We want to add value, and you need to look at more than one operation at a time. Once you understand what your customers are looking for, you can see a whole value stream where you can contribute.”