Swift-Jet

Thanks to Swift-Cut, it’s never been more affordable or achievable to own a water-jet cutting system. Waterjet technology produces excellent fine-feature cut quality with low edge taper, no heat-affected zone, a narrow kerf, and dross-free cutting.

It also offers the ability to process nearly any material and a thickness range capability unmatched by other cutting technologies.

The Swift-Jet machine with its easy to use software, powered by Hypertherm HyPrecision pumps provides high quality cutting on a wide range of materials at a low-cost investment. Easy to use with exceptional aftercare and support, the Swift-Jet is the answerto affordable, high precision in-house cutting.

Features

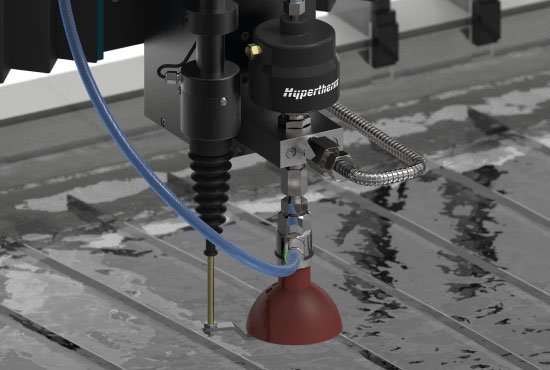

Head Protection

Collision probe protects the cutting head in the event of a crash.

Component protection

Bellows and covers prevent ingress for component protection.

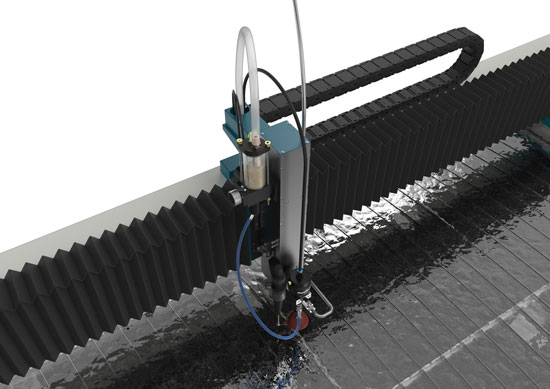

Steel water tank

Epoxy coated heavy duty steel water tank is long lasting and delivers stability for precise cutting.

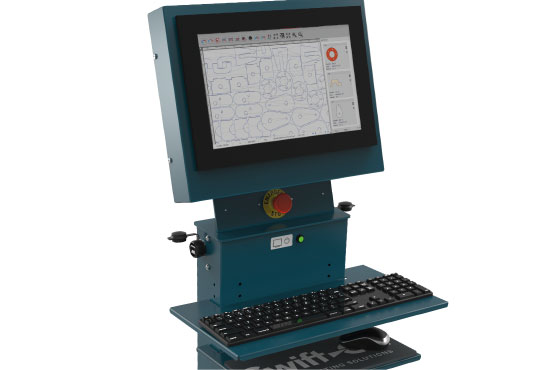

Standalone operators console

Ergonomic standalone operators console with touch, keyboard and mouse inputs.

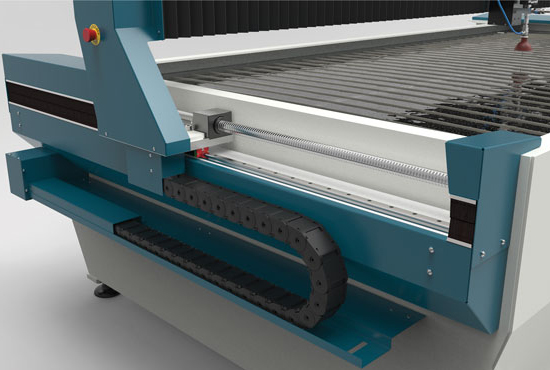

Unmatched positioning accuracy

Omron AC servos with high resolution encoders drive precision ball screws on all axes for unmatched positioning accuracy.

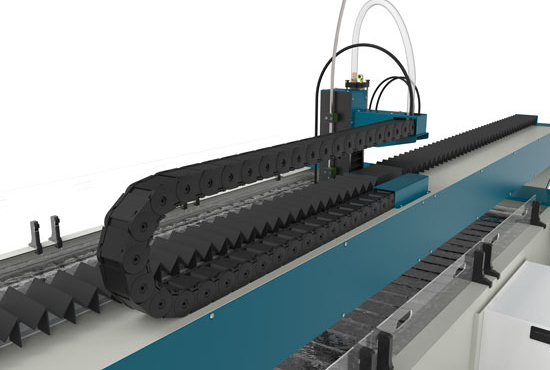

Enclosed cable protection

Enclosed cable drag chains protect cables reducing potential downtime.

Machine performance

Maximum traverse speed 15m/min (590 ipm)

Maximum Z clearance 220mm (8.5 inches)

Positional accuracy 0.0150mm (0.001 inches)

Tank Depth 840mm (33 inches)

Power Options

Hypertherm HyPrecison pump

HyPrecision 30hp

HyPrecision 50hp

Software

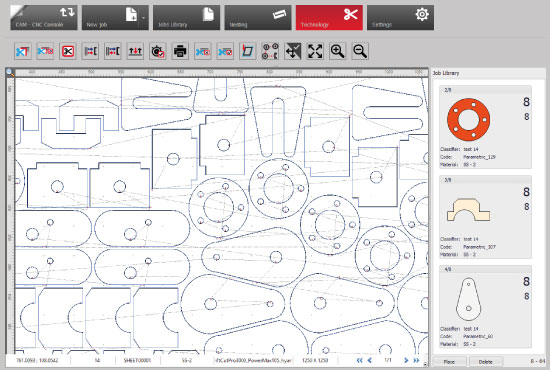

Swift-Cut Software is among the best in the industry – easy to learn, easy to use and with minimal training requirements, machines can be in production within hours of delivery.

COMPLETE SOFTWARE LIST

Automatic nesting

Automatically nests parts for economical sheet usage

Automatic lead in/out

Software automatically applies lead ins/out for quicker programming

Micro joints

Tabs to prevent parts moving whilst cutting

Bridges

Continuous cutting between parts to reduce cycle times

Common-line cut

Cut along shared edges of parts.

Sheet Alignment

Align the cutting path with misaligned sheets on the cutting bed.

Reference points

User configurable reference points for jig fixtures.

Cut modes

5 cut quality modes from fine to rough

Parametric shape library

Over 80 configurable shapes

Part in part nesting

Nest parts in scrap areas to fully utilise the sheet

Customisable cutting rules

Optimise cutting parameters for best cutting performance

Toolsets

Pre-programmed toolsets for common materials

Customisable toolsets

Modify or create toolsets for new materials.

Job reports

Export job reports displaying scrap percentage and cutting times.

3D Cut Simulation

Play a 3D machine simulation of the cutting operation.

3D part preview

Preview the part in 3D before cutting

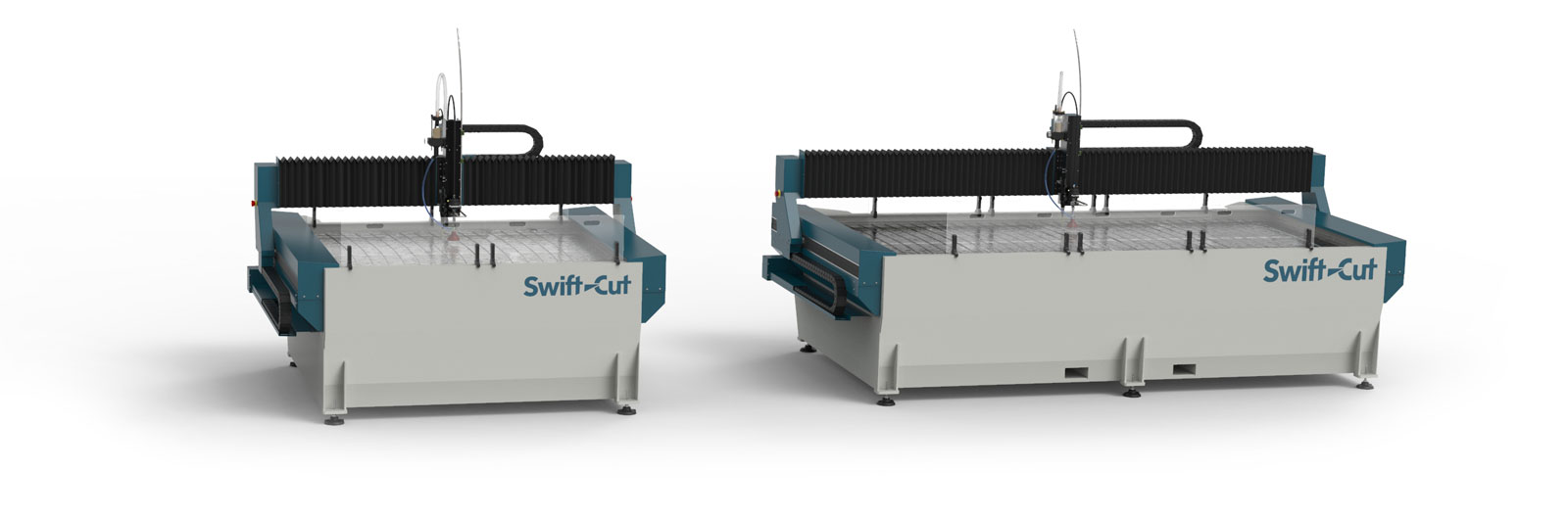

Range Sizes

SJ1500

1525mm x1525mm

cutting area (5’ x 5’)

SJ3000

1525mm x 3050mm

cutting area (5’ x 10’)

Why Buy A

Swift-Cut

Swift-Cut is the affordable way to achieve in-house cutting – a low cost investment with an incredible return.

Machines In

Action

See our range of machines in action, cutting varying thicknesses of metal in our videos section here.

What Our Customers Say

Let our customers give you an insight into how owning a Swift-Cut machine can enhance and expand your business.

Get More Information

If you want to speak to one of our team, join our mailing list or book a demonstration – here’s how…