Why Buy A Swift-Cut?

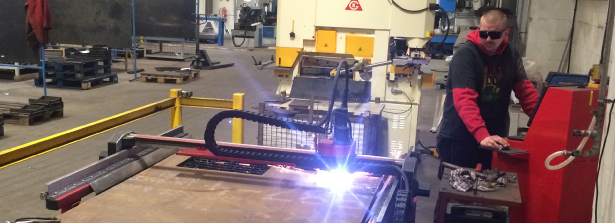

Swift-Cut’s mission is simple – from inception we pledged to provide smart cutting solutions by building affordable, high quality machines, with a customer service that is unrivalled. Whilst our company has grown in size and range, as well as expanded overseas, our fundamental and founding objective is resolute and still drives everything we do

Our top 8 reasons why

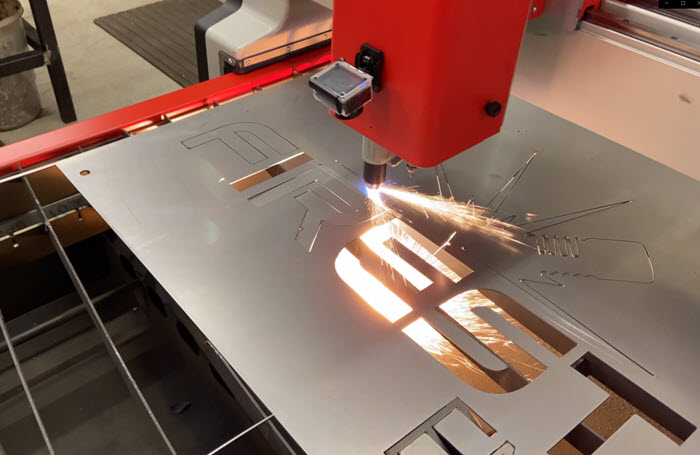

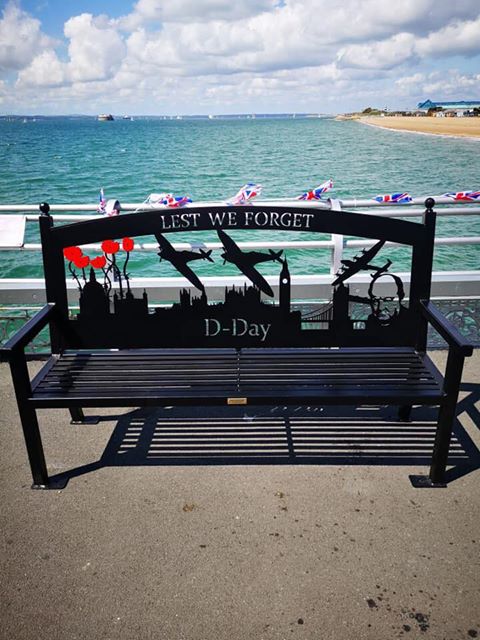

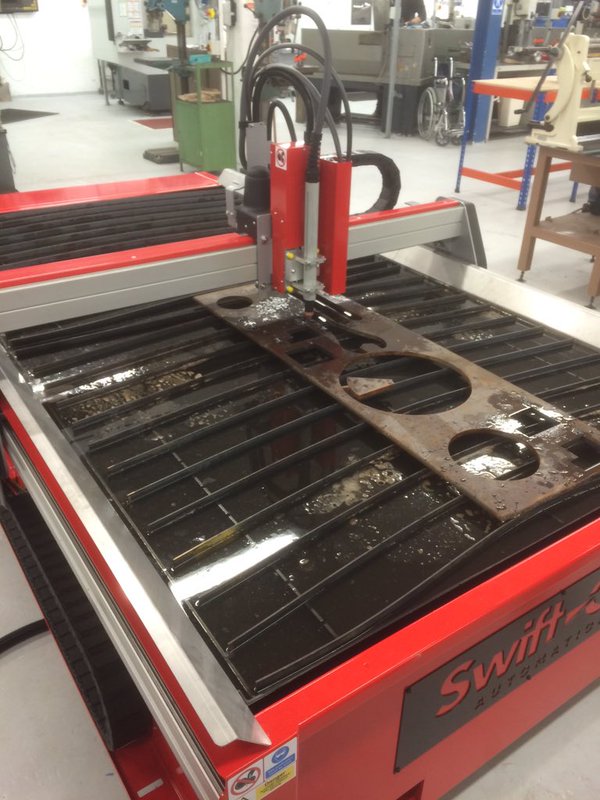

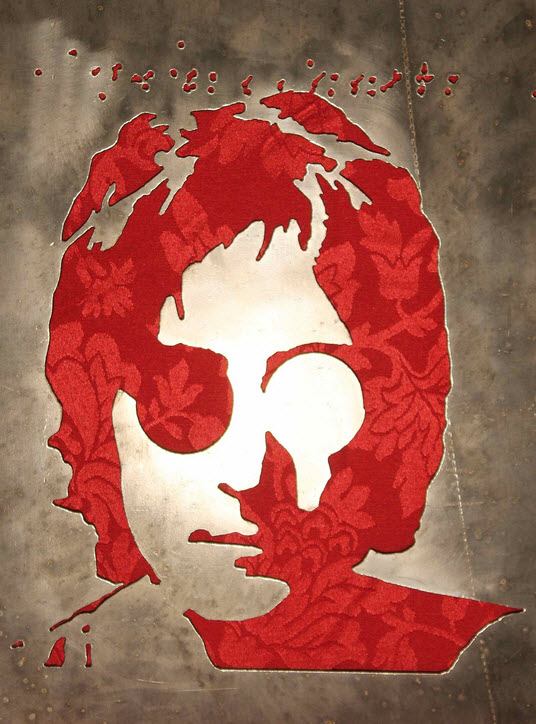

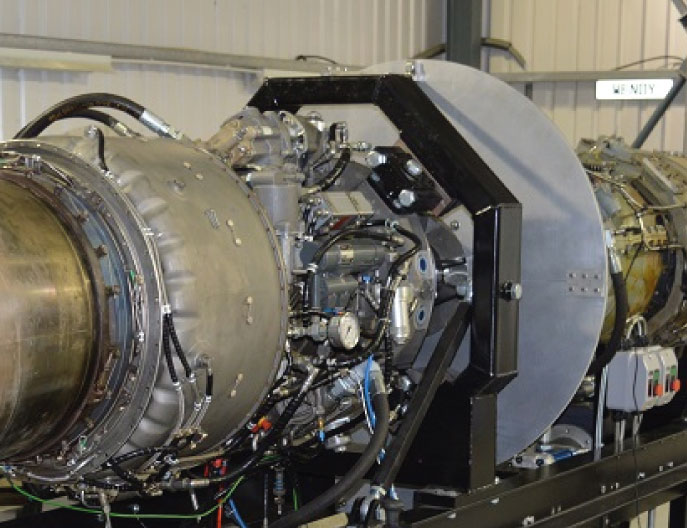

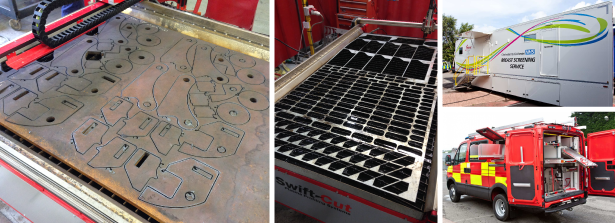

The Swift-Cut machine is the affordable plasma cutting machine with the incredible opportunity for a rapid return on investment. Our customers have seen their machine pay for itself in as little as six weeks due to its phenomenal potential for fast business growth as well as previously unrealised possibilities for product diversification.

The Swift-Cut range offers phenomenal value for money – a low cost, high quality machine with cutting capabilities that defy the price tag.

Having in-house cutting capabilities takes back control of your own production, removes the expense of outsourcing and gives your business the opportunity to grow and expand at a phenomenal rate

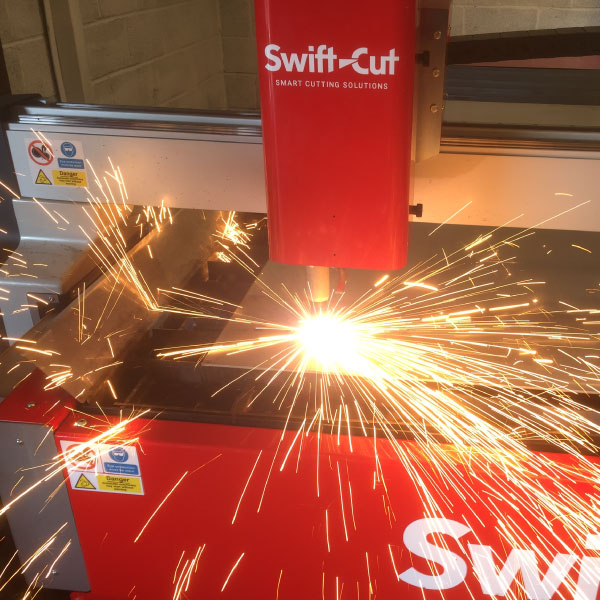

Our Swift-Cut tables benefit from the skill of our design and engineering team who strive to continuously innovate and build the very best CNC plasma tables on the market.

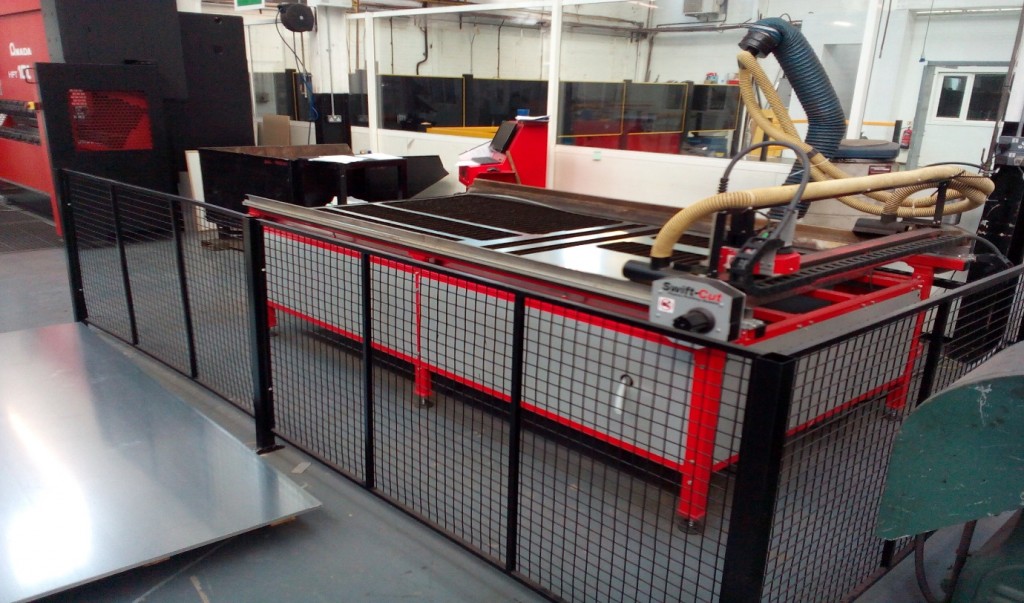

The Swift-Cut machines are built to incredibly high standards. In fact our very first Mk1 table sold in 2011 is still going strong. All our tables feature durable, robust designs and we have different ranges depending on whether you want to cut for an hour here or there, or 16 hours a day.

The robust build of the Swift-Cut machine is matched only by the high-speed precision of the cut and to make sure every Swift-Cut plasma cuts to these exact standards, we Renishaw ball-bar test every one of our tables before despatch to certify the positional accuracy and circularity. Question any manufacturer that doesn’t do this.

The Swift-Cut system is so easy to learn and use, we believe half a day training is ample to get you up and cutting.

Swift-Cut support is the industry leading package which aids and assists our customers throughout their journey. Using a combination of telephone, online (remote login) and App support (via downloadable app for iOS and Android) we can rectify 95% of application issues remotely with minimum response times for both UK and global customers

Why buy a Swift-Cut

Swift-Cut’s mission is simple – from inception we pledged to provide smart cutting solutions by building affordable, high quality machines, with a customer service that is unrivalled. Whilst our company has grown in size and range, as well as expanded overseas, our fundamental and founding objective is resolute and still drives everything we do.

Our top 8 reasons why

The Swift-Cut machine is the affordable plasma cutting machine with the incredible opportunity for a rapid return on investment. Our customers have seen their machine pay for itself in as little as six weeks due to its phenomenal potential for fast business growth as well as previously unrealised possibilities for product diversification.

The Swift-Cut range offers phenomenal value for money – a low cost, high quality machine with cutting capabilities that defy the price tag.

Having in-house cutting capabilities takes back control of your own production, removes the expense of outsourcing and gives your business the opportunity to grow and expand at a phenomenal rate

Our Swift-Cut tables benefit from the skill of our design and engineering team who strive to continuously innovate and build the very best CNC plasma tables on the market.

The Swift-Cut machines are built to incredibly high standards. In fact our very first Mk1 table sold in 2011 is still going strong. All our tables feature durable, robust designs and we have different ranges depending on whether you want to cut for an hour here or there, or 16 hours a day.

The robust build of the Swift-Cut machine is matched only by the high-speed precision of the cut and to make sure every Swift-Cut plasma cuts to these exact standards, we Renishaw ball-bar test every one of our tables before despatch to certify the positional accuracy and circularity. Question any manufacturer that doesn’t do this.

The Swift-Cut system is so easy to learn and use, we believe half a day training is ample to get you up and cutting.

Swift-Cut support is the industry leading package which aids and assists our customers throughout their journey. Using a combination of telephone, online (remote login) and App support (via downloadable app for iOS and Android) we can rectify 95% of application issues remotely with minimum response times for both UK and global customers