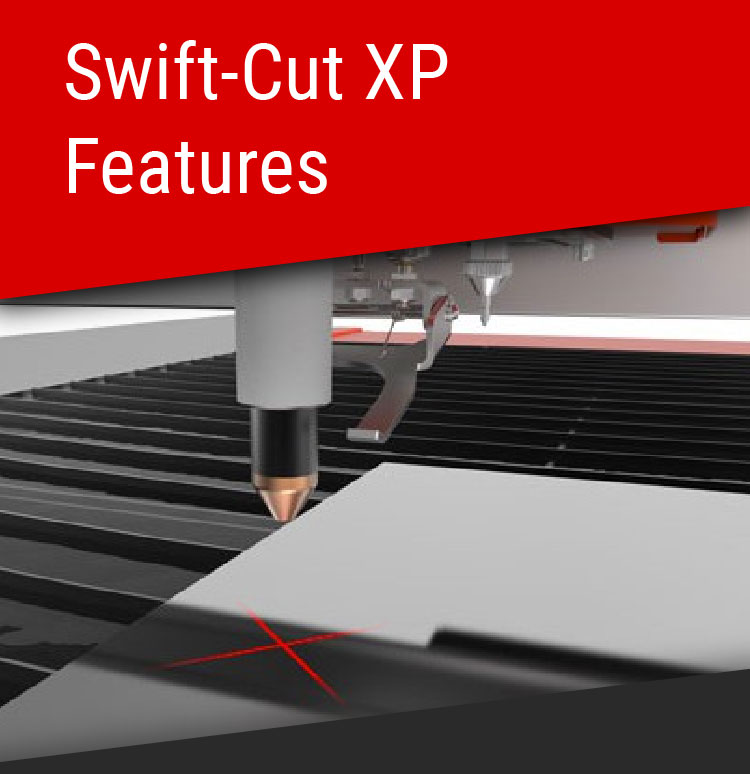

Breakaway head

Prevent premature torch failure with our breakaway head system

Digital torch height control

Follow the contour of sheet metal automatically

Floating initial height sense

Reliable touch off sensing system for accurate pierce heights

Enclosed cable management

All cables completely covered to prevent damage from molten debris

Freestanding console

Place the console in the most convenient position around the table with the plug and play operator interface assembly

Fume management

Segmented downdraft system that allows extraction at the point of cut giving you efficient, cost effective and safe cutting environment

Fork lifts pockets

Effortless relocation and transportation of the table

Linear guide rails

Offers great cut quality at high speed

Helical rack

Cut accurately and smoothly to get an extra edge in cut quality and performance

Drive system

IGBT driven sinusodial Omron 400W drive

Servo motor

Digital torch height control driven by 100W OMRON servo drive system

Ability to cut using Air/Air, O2/Air and N2/Air

Improves edge finish

Faster cut speeds

Less dross

Less taper

Longer consumable life

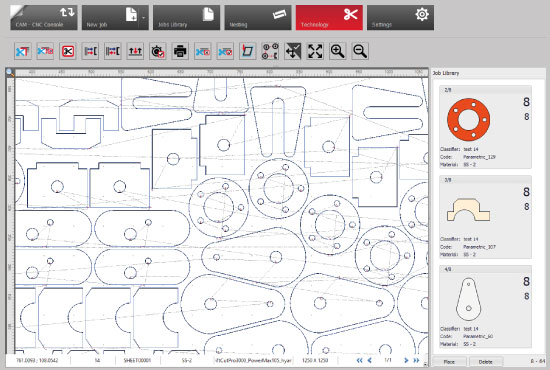

Swift-Cut’s easy to use software guarantees that anyone with a basic knowledge of computers will be capable of operating the CNC plasma cutting system. Minimal training means the machine will be operational almost immediately, maximising output from the start.

Available in three versions

Simple and easy to learn and use, zero training requirements

Allows you to simply import and auto nest parts, saving on time and costs

Easy and fast loading procedure

Correct programming of machines without any investment efforts required to learn a new system

Offers a wide library of parametric patterns