Change the way you work with the

NEW, revolutionary Powermax SYNC™ series

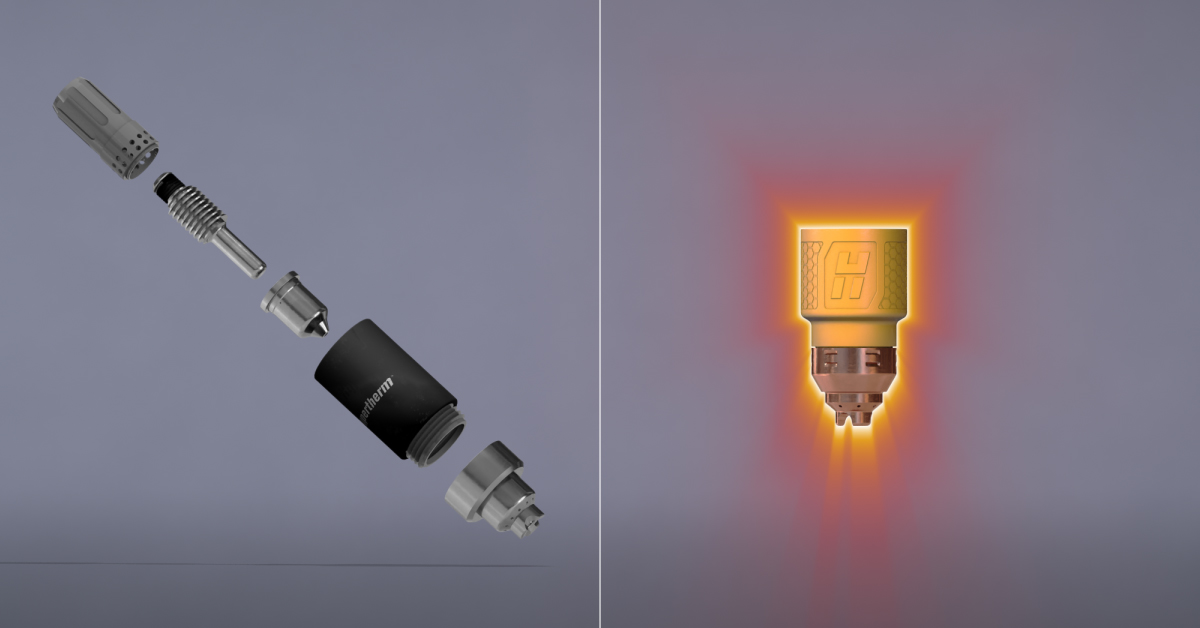

Powermax SYNC™ series, the next generation of Powermax65/85/105 systems, is unlike any plasma you’ve seen before. Featuring built-in intelligence and a revolutionary single-piece cartridge consumable!

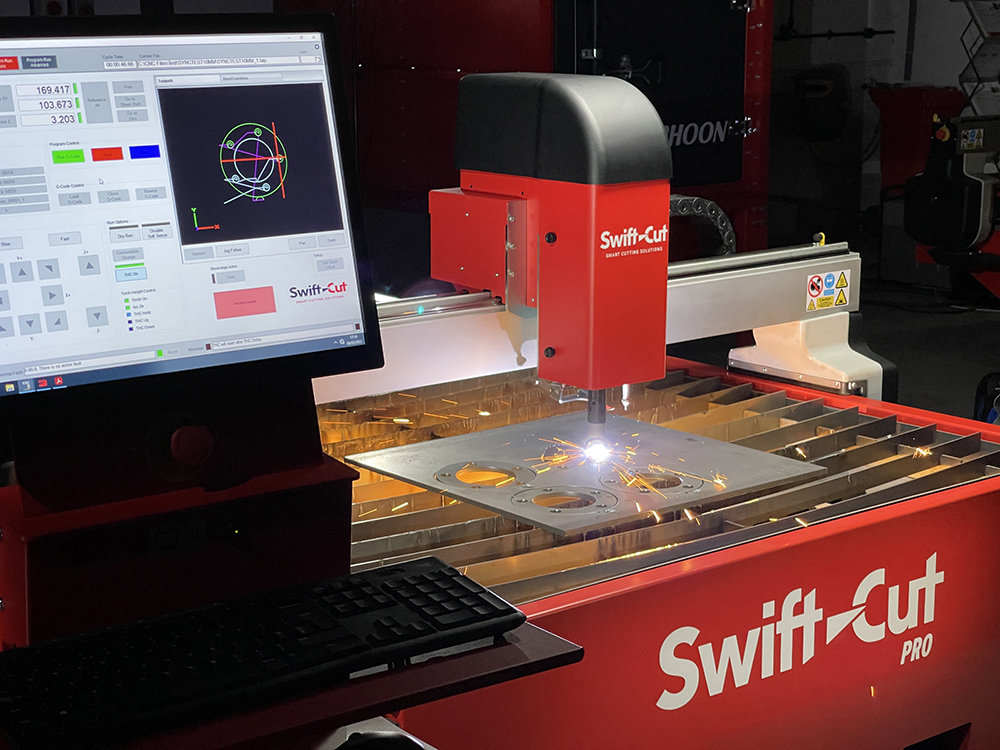

Swift-Cut is the worlds first light industrial CNC OEM to fully test and integrate the new Hypertherm Powermax SYNC™ plasma systems with our cutting machines and software.

As a key partner of Hypertherm for over 10 years, we have worked closely with the global number 1 for plasma power sources and been part of their SYNC™ early adopter program.

Extensive testing of fully nested sheets has allowed us to analyse the performance of the new systems and we would now like to introduce our brand new Swift-Cut SYNC™ video which provides an overview of the advantages available to us now the SYNC™ system is available to purchase.

All new Swift-Cut plasma machines are SYNC™ ready. The SYNC™ power sources are also retrofittable on existing tables (software update required)

8 reasons to upgrade

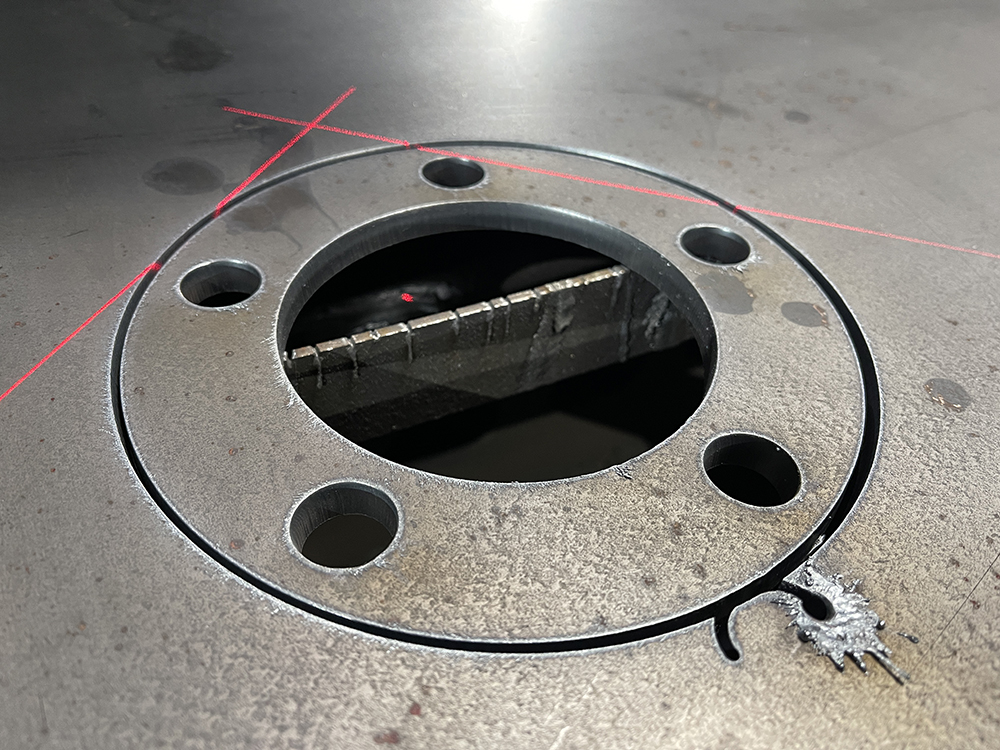

Increased cut height (on material less than 1/2″)

Reduces the potential for nozzle damage and collision with molten metal produced during the pierce and cutting process

Consumable longevity

We have experienced over 2000+ pierces per set of consumables. This means;

- Less consumable changes – less downtime for the customer – increased productivity

- Lower cost per part

Improved cut quality

Edge finish is smooth and angularity is controlled

Ease of Use

The new cartridge system is easy to install and remove. There’s reduced chance of dropping individual consumables into the table bed. Colour coordinated cartridge makes the correct cutting process (mechanised vs hand-cut etc) easily identifiable

Money saving

Cartridge reduces the chance of used consumables being swapped out too early. Maximise the life of each set and reduces wastage. Consumable age and usage can be checked on the CNC software or through the dedicated Hypertherm app*

Innovative smart system

Innovative smart system and access to cartridge data for performance tracking and analysing usage patterns*

Foolproof design!

For the first time ever, the machine knows what consumables are on the end of the torch! If the wrong consumables are installed, the machine will recognise this and ask if you wish to change**

Less stock inventory

One part per amperage to stock instead of up to five

*Optional cartridge reader accessory required along with smartphone and Hypertherm SYNC app for viewing data away from the operators console

**Phase 2 – coming soon