RAISE YOUR STANDARDS, LOWER YOUR COSTS

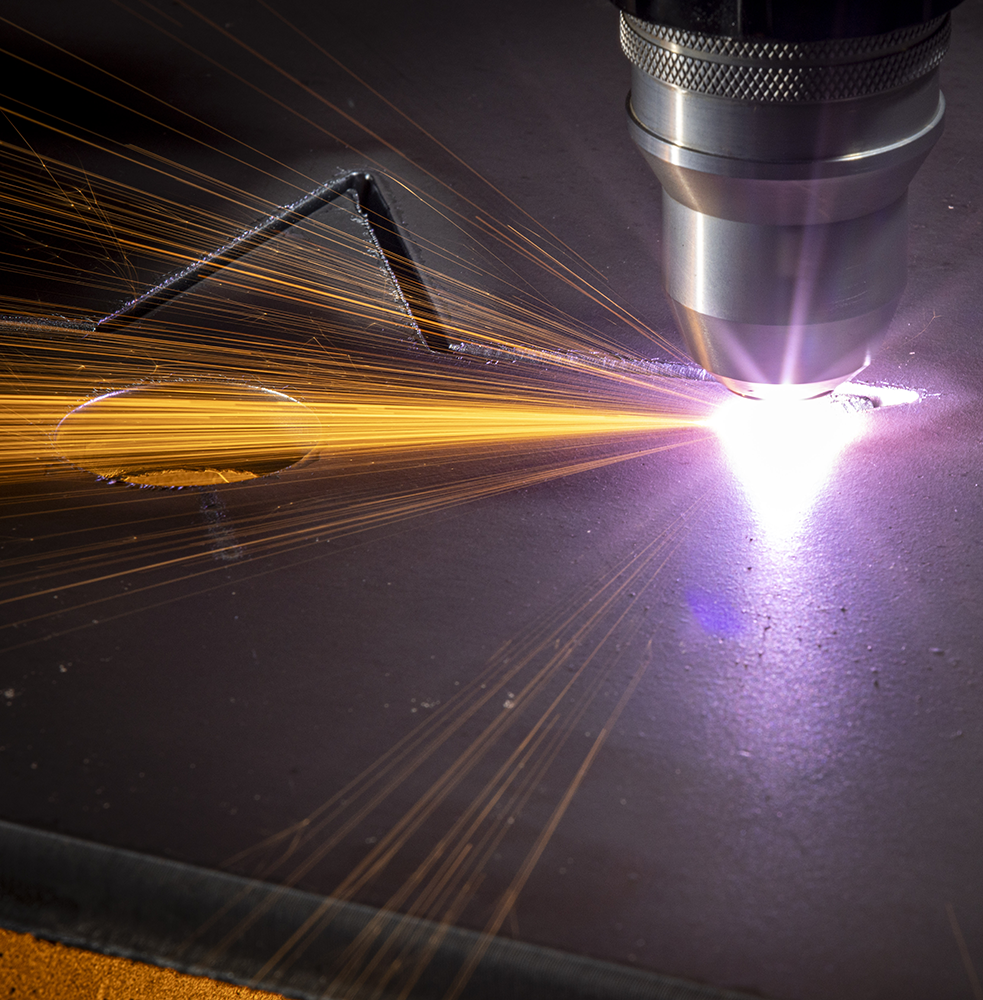

- High Precision fully featured plasma system for the price of a high-end standard definition water-cooled system. High-Definition CNC plasma cutting at an unbeatable price.

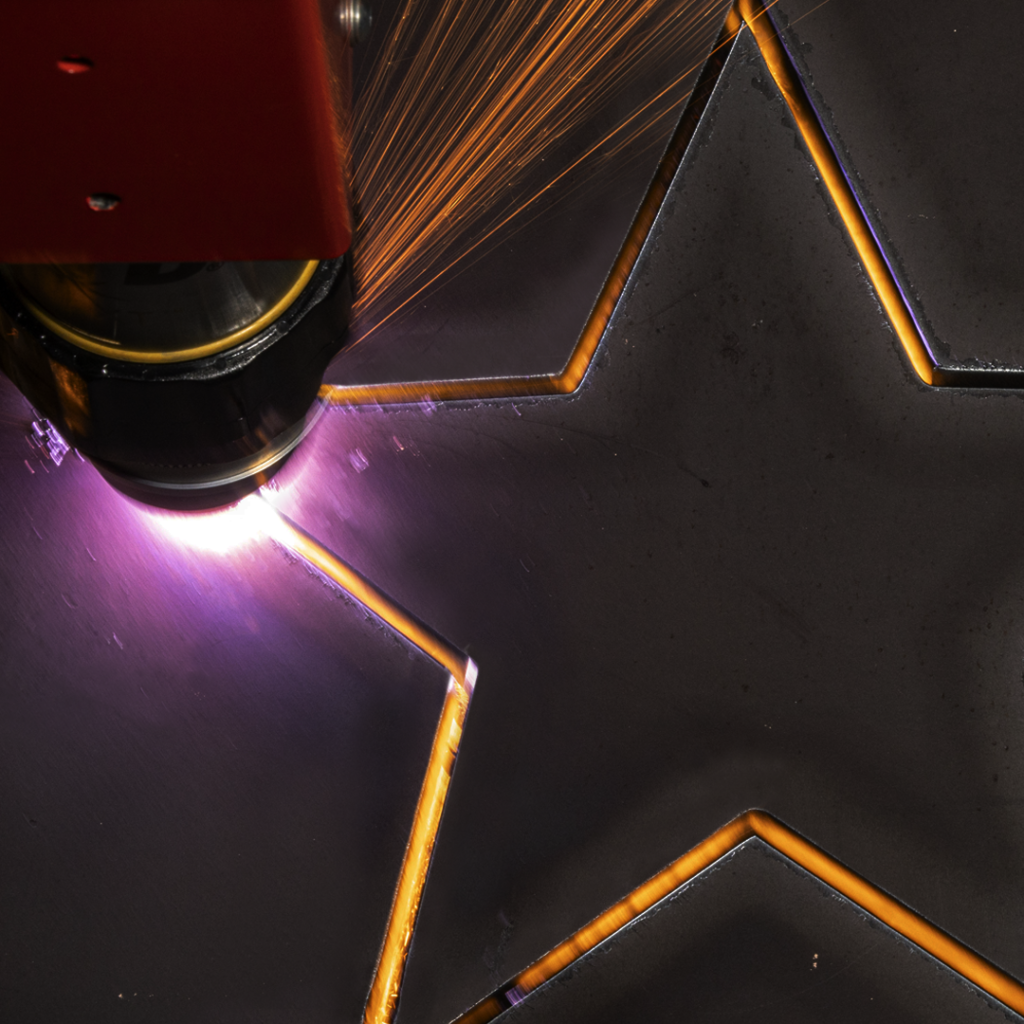

- Diameter PRO™ cutting technology produces precise “Bolt Ready” holes with minimal taper. Optimised for a diameter-to-thickness ratio of 1:1 or greater*

- Water Mist Secondary (WMS) functionality produces outstanding cut quality on non-ferrous metals, with virtually no Heat-Affected-Zone (HAZ)**

- Superior cut quality removes the need for secondary processes allowing maximum productivity*

- Outstanding parts life, rapid cut speed, and reduced gas consumption lowers the cost of ownership

Why buy a Precision 130?

Why would you buy this over a standard definition plasma?

You need the cut quality, edge finish, accuracy, hole tolerance and speed a standard definition system just cannot deliver. The Precision 130 has up to 70% lower running costs than an equivalent amperage, standard definition, air cooled system, whilst it can cut up to 20% faster.

Why would you buy this over a competitor HD system?

Simply, it offers unrivalled value for money. A fully featured High-Definition plasma power source with the addition of Water Mist Secondary cutting (WMS) for amazing cut quality on Stainless Steel and Aluminium too. On top of this, leading brand, 3-year warranty, supported platform 15+ years and supported globally.

Why would you buy this over a laser?

Flexibility. It doesn’t matter if you’re cutting thick or thin material, with HD plasma you get the same great cut quality, cutting speeds, and low running costs, every time. In addition, lasers are more expensive to buy, have greater servicing costs, require more frequent maintenance, and require specialist installation and setup to get them working correctly. The Precision 130 can cut 30% faster than a 6kw laser on 15mm mild steel, and lasers struggle to deliver a consistently smooth cut surface on thicker materials. Lasers cost more to run when cutting stainless steel due to high usage of Nitrogen gas and can use up to double the amount of electricity when cutting plate thicknesses greater than 12mm.

Additional Benefits

- Speedlok torch technology ensures toolless consumable changes, ‘leakless’ head design, and superior warranty

- Cut from 1.5mm to 20mm mild steel (up to 15mm Stainless and up to 15mm Aluminium). Best productivity and production pierce at 15mm

- The lowest cost High-Definition plasma with WMS functionality on the market today

- 3-year guarantee

- Costs 23% less to run than a 200 Amp standard definition water cooled system

- Bringing High-Definition water-cooled torch, oxygen cutting into a price range not seen before

System Details

- Amperage range: 30 – 130 Amps

- Duty Cycle: True 100%

- Consumable stack – (7) – Cartridge, Electrode, Plasma Gas Distributor, Tip, Shield Gas Distributor, Shield Cap, Shield Cups

- Weight: 141 kg

- Dimensions: 864 x 560 x 762mm

- Certifications: CE and CSA

* when utilising oxygen cutting gas and compressed air shielding gas on mild steel

** when utilising nitrogen cutting gas and water shielding on stainless steel and aluminium