Swift-Cut XP

The Swift-Cut XP is cutting edge in its design and more durable than ever. The new XP is designed with production cutting in mind up to 32mm, now available to work in conjunction with the Hypertherm MAX PRO 200. Supplied with OMRON AC servo motors across all axes for improved accuracy.

The liquid cooled mechanised torch is mounted to a redesigned heavier duty gantry to provide a sturdy platform for high amperage cutting, this allows for a pierce capacity up to 32mm and improved cut speeds, with mixed gas cutting available on all plasma options. The increased clearance height from bed to gantry allows up to 150mm box section to be cut. Add to that the opportunity to utilise the water mist technology, which will not only give you a precise cut but is the optimum technology for working with stainless steel and Aluminium, and the Swift-Cut XP really is all its cut out to be.

Features

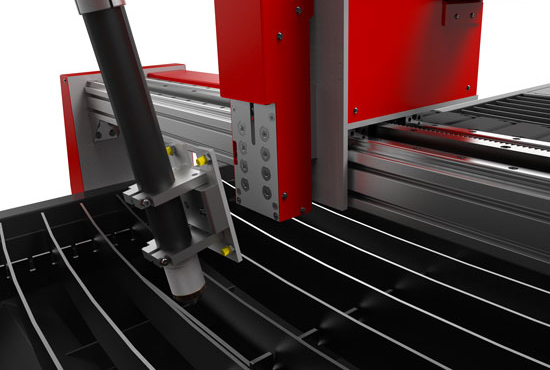

Breakaway head

Prevent premature torch failure with our breakaway head system

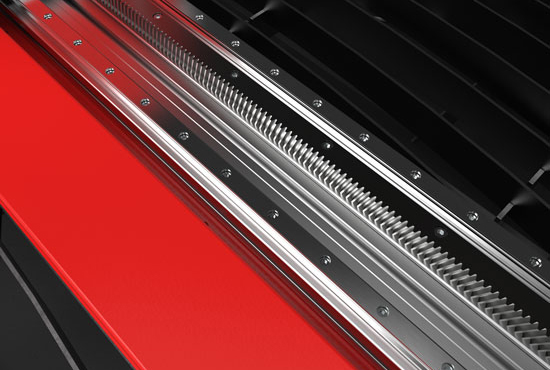

Linear guide rails

Offers great cut quality at high speed

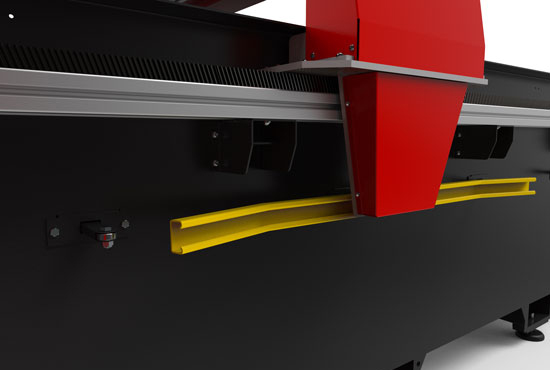

Fume management

Segmented downdraft system that allows extraction at the point of cut giving you efficient, cost effective and safe cutting environment

Helical rack

Cut accurately and smoothly to get an extra edge in cut quality and performance

Key Benefits

Ability to cut using Air/Air, O2/Air and N2/Air

Improves edge finish

Faster cut speeds

Less dross

Less taper

Longer consumable life

COMPLETE FEATURES & BENEFITS LIST

Breakaway head

Prevent premature torch failure with our breakaway head system

Digital torch height control

Follow the contour of sheet metal automatically

Floating initial height sense

Reliable touch off sensing system for accurate pierce heights

Enclosed cable management

All cables completely covered to prevent damage from molten debris

Freestanding console

Place the console in the most convenient position around the table with the plug and play operator interface assembly

Fume management

Segmented downdraft system that allows extraction at the point of cut giving you efficient, cost effective and safe cutting environment

Fork lifts pockets

Effortless relocation and transportation of the table

Linear guide rails

Offers great cut quality at high speed

Helical rack

Cut accurately and smoothly to get an extra edge in cut quality and performance

Drive system

IGBT driven sinusodial Omron 400W drive

Servo motor

Digital torch height control driven by 100W OMRON servo drive system

Key Benefits

Ability to cut using Air/Air, O2/Air and N2/Air

Improves edge finish

Faster cut speeds

Less dress

Less taper

Longer consumable life

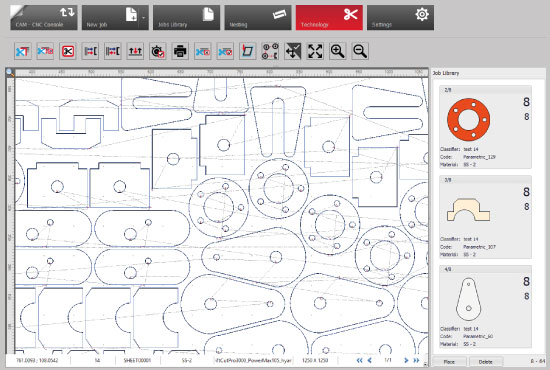

Software

SwiftCAM is CAD / CAM application software developed to allow ease of use for any of our Swift-cut cutting machines, guiding the user to production through a simple path and minimising the time normally set aside for programme preparation.

An easy to learn product, SwiftCAM allows you to verify the recently created production cycle via 3D simulation in a realistic environment to test its functionality.

COMPLETE SOFTWARE LIST

- Available in three versions

- Simple and easy to learn and use, zero training requirements

- Allows you to simply import and auto nest parts, saving on time and costs

- Easy and fast loading procedure

- Correct programming of machines without any investment efforts required to learn a new system

- Offers a wide library of parametric patterns

Range Size

3000mm x 1500mm

10’ x 5’

4000mm x 2000mm

13′ x 6.5′

Why Buy A

Swift-Cut

Swift-Cut is the affordable way to achieve in-house cutting – a low cost investment with an incredible return.

Machines In

Action

See our range of machines in action, cutting varying thicknesses of metal in our videos section here.

What Our Customers Say

Let our customers give you an insight into how owning a Swift-Cut machine can enhance and expand your business.

Get More Information

If you want to speak to one of our team, join our mailing list or book a demonstration – here’s how…