Hole tolerances

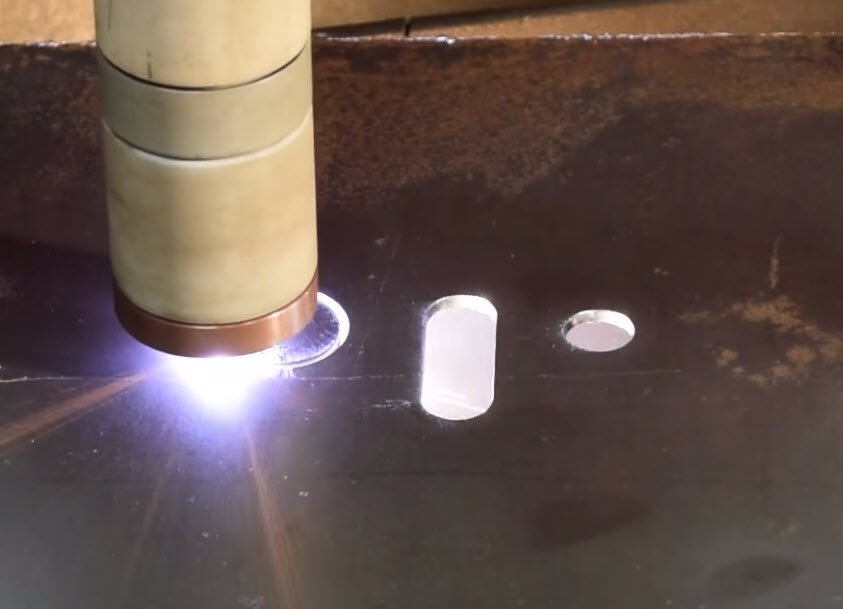

It’s a popular topic when discussing plasma cutting and one question we regularly get asked: What is the smallest hole size I can achieve using a Swift-Cut CNC plasma table?

The simple answer, and the one we publish on our website is: Our machines follow the 2D rule. As such, when cutting a plate that is 10mm thick, the smallest hole that it can cut is 20mm in diameter.

This rule is not set in stone and is more of a guide. There are numerous factors which can affect cut and hole quality, and these are outlined below:

- Air quality– Plasma cutting requires clean dry air (the correct air standard to maintain is ISO 8573-1 CLASS 1.2.2) and it uses lots of it. By installing and maintaining air filtration units within the airline, as well as specifying the right compressor/dryer solution, the quality, volume and pressure of the air will remain constant and therefore your consumable life will increase, along with hole repeatability and quality. Swift-Cut can supply a complete air solution designed specifically for your needs.

- Consumable condition– worn consumables can create angled cuts, excessive dross and poor hole quality. Swift-Cut tables benefit from Hypertherm power sources and torches which have some of the best consumable longevity of any air plasma system. Slower wear means better hole repeatability and accuracy. We stock consumables for all Hypertherm cutting solutions.

- Torch height– for small holes, cut height should remain constant throughout the cut. Swift-Cuts Soft Sense system (IHS) provides an accurate pierce and cut height for optimal consumable life and hole quality.

- Gantry movement– the smoother the torch can travel, the better the cut will be. This is why the Swift-Cut Pro and XP tables feature linear rails on all axes – to deliver more accurate and repeatable hole cutting compared to other guide systems.

- Lead in and lead out– this is where the plasma arc starts and stops. Selecting the correct setting is never more important than when cutting holes. Swift-Cut software not only allows the user to choose from over 20 different lead in and lead outs, but it also allows you to move the start and finish position on each individual cut.

- Travel speed– cutting speed for a hole is very different to cutting speed in a straight line. Swift-Cut software automatically calculates the optimum cut speed for any given hole (internal or external) based on area

- Cutting amperage– Swift-Cut R&D team and technicians work closely with Hypertherm to determine the optimal cutting parameters for any given material type and thickness. Our software automatically adjusts these parameters and informs the operator of the correct consumables to use to ensure the hole accuracy is at its best.

- Service– machinery needs to be maintained correctly to ensure best performance – Swift-Cut offer an excellent service and support package to make sure you get the most from your cutting solution, year on year.

Ensuring all of the above areas are in place will mean your hole cutting will be the best it can be.

Once all the above has been taken into consideration it’s still possible, due to the nature of a plasma arc, that you will experience some taper on your cut holes. Swift-Cut’s Centre Mark feature can assist by allowing the operator the choice to plasma mark the centre of any given hole (no matter the size) with a simple centre dot, which can then be used as a datum point for drilling, using a standard HSS drill bit or MAG drill cutter.

Contact us now to book an online demonstration or better yet come and see our Experience Centre and let us show you just how good Swift-Cut plasma tables really are.