TOR Design and Fabrication, a metal fabrication firm in the Wirral area of North-West England owned by Johnny Skinner, undertakes a diverse range of works from architecturally specified metalwork and staircases to product design and artists commissions. Working with architects and engineers, artists and product owners and private individuals, Johnny creates and makes one-off and production batch work to order.

The Challenge

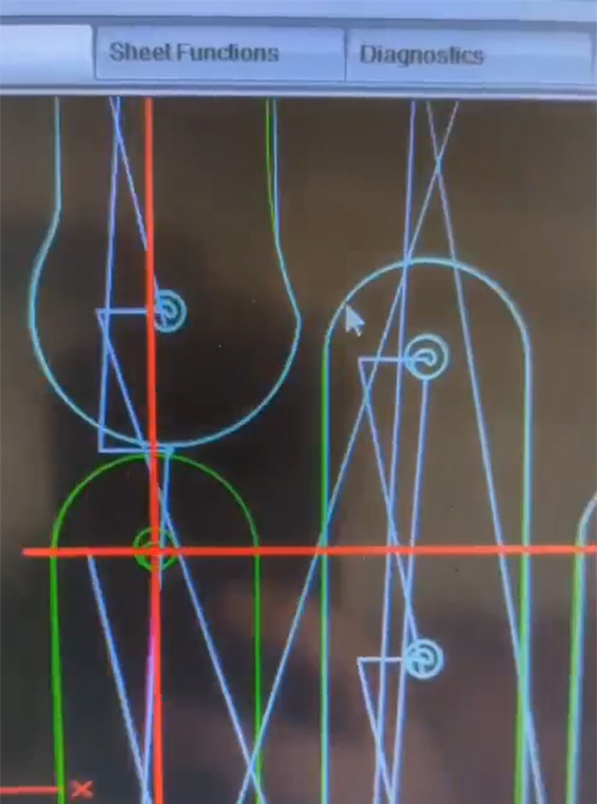

Before bringing cutting capabilities in-house and during his early training, Johnny relied on guillotines and sheet metal tools. An architecture study graduate, he had thought about the possibility of using CNC cutting – namely the speed of converting AutoCAD design into real objects with in-built assembly potential.

Outsourcing laser cutting was costly and unreliable. Schedules were slowed and erratic service to customers and long turnaround times led Johnny to comment, “I wanted to have the independence to finish jobs without having to rely on other firms.”

The Solution

The desire to own in-house CNC capability led Johnny to Swift-Cut. Having already experienced the quality of Hypertherm hand-held plasmas, he wondered if he could utilise a CNC plasma system. A laser cutter was out of his budget, but Swift-Cut was a good and budget-friendly option.

He was sold on a visit to the Swift-Cut showroom and a look at the machines in use. “I was impressed by the quality – and the price,” he says.

The Outcome and the highlights

The purchase of the Swift-Cut Pro has been a blessing to TOR Design and Fabrication.

“It’s an integral part of the workshop – it’s a tool that allows me to cut out my parts at the click of a button. I couldn’t imagine a workshop without it now!”

· Rapid prototyping: Quick testing and iterating of designs are possible.

· Shorter lead times: Internal cutting eliminates any delays on subcontracted parts

· Greater flexibility: Fixtures and fittings are developed when and as required.

· Increased creativity: The adaptability of the machine has also increased the projects’ dynamism and appeal.

Installation and Support

Even though Johnny had never operated a CNC machine before, he found it very easy to set up and install. Guided by the remote support of Swift-Cut, he encountered no problems during the learning phase.

“Regardless of the question, the remote service team explained it to me. When I had a part I needed replaced, they had it delivered here the very next day – and explained the installation to me on the phone.”

Would you recommend Swift-Cut?

“Yes! If you’re considering buying a CNC plasma cutter, I would highly recommend Swift-Cut for its versatility and usefulness in the day to day operations of a welding workshop.”

Follow TOR Design & Fabrication on instagram