Swift-Cut Pro

The Swift-Cut Pro range is a collection of four cutting edge in design CNC plasma cutting machines. With easy to use software, the Swift-Cut Pro series promises high speed precision cutting at a low cost investment. Easy to use, simple to learn and operate with exceptional aftercare and support, the Swift-Cut Pro Series is the answer to affordable in-house CNC metal cutting.

Features

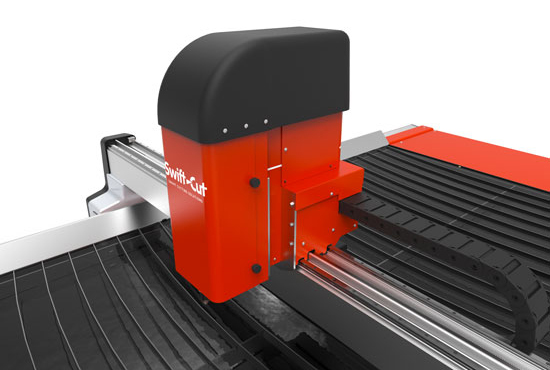

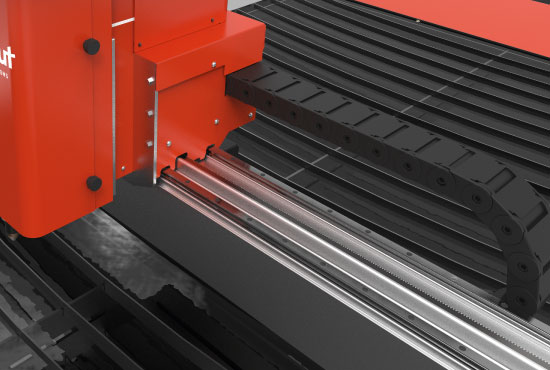

Fully enclosed head

Fully enclosed cutting head offers protection to key components against the harsh cutting environment.

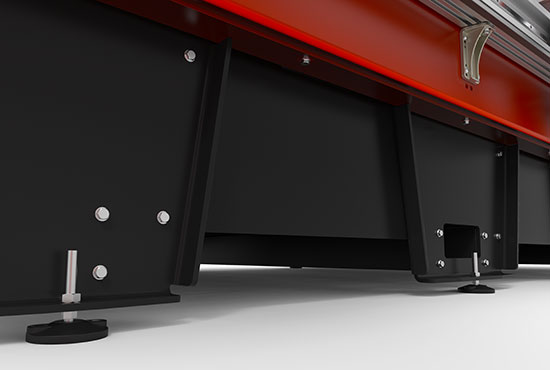

Heavy duty base

Heavy duty gantry end castings with machined faces provide a precise and stable platform for the cutting head.

Operators Console

Ergonomic operators console with touch screen and keyboard/mouse inputs.

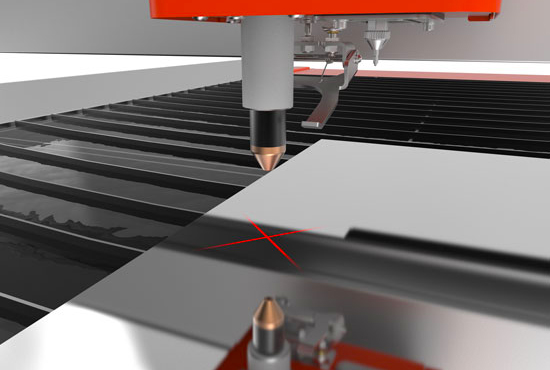

Soft touch plate sensor

Pneumatically driven “Soft Sense” soft touch plate sensor to accurately locate the plate surface even on thin materials.

Precision linear rail

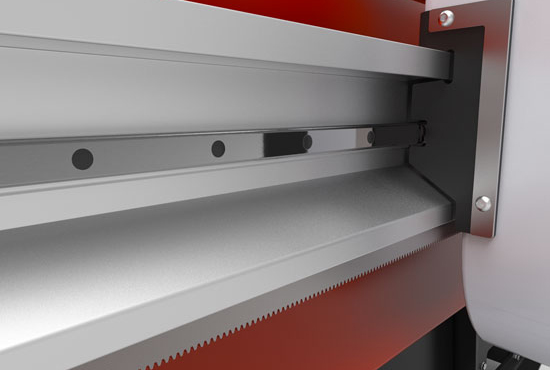

Precision linear rail on all axes combined with stepper motor encoder feedback delivers exceptional positioning accuracy.

Laser positioning

Laser cross hairs aid in the positioning of the cutting head.

Engraving tool

The Swift-Cut engraving tool allows you to mark and cut in one operation, meaning no more outsourcing or moving your project from one machine to another. (Optional extra)

Lightweight & rigid gantry beam

Lightweight but rigid gantry beam supports twin x-axis linear rails.

COMPLETE FEATURES LIST

Fully enclosed cutting head

Fully enclosed cutting head offers protection to key components against the harsh cutting environment.

Heavy duty base

Heavy duty base redesigned from the ground up provides support and rigidity.

Operators console

Ergonomic operators console with touch screen and keyboard/mouse inputs.

soft touch plate sensor

Pneumatically driven “Soft Sense” soft touch plate sensor to accurately locate the plate surface even on thin materials.

Precision linear rail

Precision linear rail on all axes combined with stepper motor encoder feedback delivers exceptional positioning accuracy.

Laser positioning

Laser cross hairs aid in the positioning of the cutting head.

Lightweight & rigid gantry beam

Lightweight but rigid gantry beam supports twin x-axis linear rails.

Engraving tool

The Swift-Cut engraving tool allows you to mark and cut in one operation, meaning no more outsourcing or moving your project from one machine to another. (Optional extra)

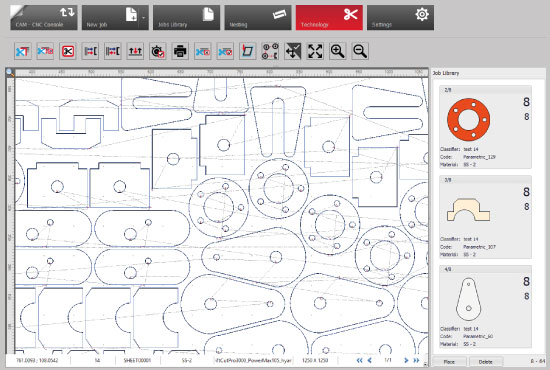

One-piece CAM/CNC software

One-piece CAM/CNC software offers a feature packed and intuitive interface…… (available late 2018)

Automatic torch height control

Automatic torch height control maintains the correct cutting height resulting in improved cut quality and consumable life.

Heavy duty gantry end castings

Heavy duty gantry end castings with machined faces provide a precise and stable platform for the cutting head.

Enclosed cable protection

Fully enclosed drag chains protect cables against damage from molten material.

Fume extraction

The water table bed option offers efficient fume suppression so that no external fume extraction is required. Alternatively, the zoned downdraft table option (only available in the 3000m machine size) captures fumes and particles from beneath the cutting area.

Power Options

Hypertherm

Powermax 45XP

Powermax 65

Powermax 85

Powermax 105

Powermax 125

Software

Swift-Cut Software is among the best in the industry – easy to learn, easy to use and with minimal training requirements, machines can be in production within hours of delivery.

COMPLETE SOFTWARE LIST

Serial link with Hypertherm Powermax

Automatic control of plasma settings.

Easy to use

Easy to use with basic and advanced screens

Sheet Alignment

Align the cutting path with misaligned sheets on the cutting bed.

Sheet Trim

Easily trim scrap material from sheet stock

Cut Recovery

Easily recover interrupted cuts due to a breakaway head or emergency stop condition.

G-Code Favourites

Save up to 5 g-code files for quick loading

Dry run

Run the g-code file without cutting

Automatic lead in/out

Software automatically applies lead ins/out for quicker programming

JPEG/DXF/DWG import capable

Import .dxf files or convert .jpg images for cutting

Automatic nesting*

Automatically nests parts for economical sheet usage

Part in part nesting

Nest parts in scrap areas to fully utilise the sheet

Customisable cutting rules

Optimise cutting parameters for best cutting performance

Customisable toolsets

Modify or create toolsets for new materials.

3D Cut Simulation*

Play a 3D machine simulation of the cutting operation.

3D part preview

Preview the part in 3D before cutting

Parametric shape library

Over 80 configurable shapes

Reference points

5 user configurable reference points for jig fixtures.

G-Code Queue

Queue up to 5 g-code files for quick loading.

*Advanced Only

Range Sizes

1250mm x 1250mm

4’ x 4’

2500mm x 1250mm

8’ x 4’

3000mm x 1500mm

10’ x 5’

4000mm x 2000mm

13’ x 6.5’

(due for release late 2019)

Why Buy A

Swift-Cut

Swift-Cut is the affordable way to achieve in-house cutting – a low cost investment with an incredible return.

Machines In

Action

See our range of machines in action, cutting varying thicknesses of metal in our videos section here.

What Our Customers Say

Let our customers give you an insight into how owning a Swift-Cut machine can enhance and expand your business.

Get More Information

If you want to speak to one of our team, join our mailing list or book a demonstration – here’s how…