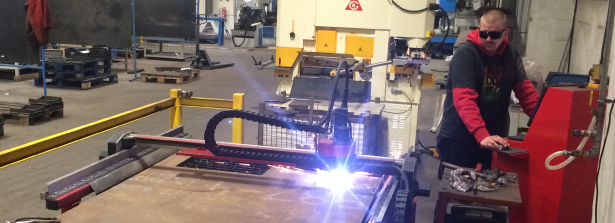

LISEGA, a multi-national specialising in pipe supports for major plant, engineering and construction, has a UK subsidiary that fabricates bespoke supports. David Robson, the Operations Manager in the UK, purchased a Swift-Cut 1250 table in December 2013 after seeing the machine demonstrated at an industry show and being impressed with its performance.

Before buying their Swift-Cut table LISEGA relied on external suppliers and out-sourcing, owning their own table has meant that they have been able to keep the majority of their work in-house. Not only that, the turnaround is impressive; when once a project might take 5-7 days because it had to be sent off, now they have their own plasma cutting table in situ, they can literally respond to production requests within the hour. David says that the machine comes into its own when small, last minute orders are placed and that “as a business, not having to turn away work because the time scales won’t allow is obviously a godsend.”

He goes on to say that the simple software, easy installation and limited training needed were all key in the decision to purchase a Swift-Cut table. He also liked the Swift-Cut approach, he found them to be innovative and forward thinking. He had looked at other producers but found them to be “stuck in their ways”. He appreciated the way Swift-Cut listen to their customer at the initial ordering stage and take the time to find out what the customer wishes to achieve from owning one of their tables, ensuring that you buy the right machine, with the right software and the right add-ons. Throw in the impressive installation process and efficient after care service and David feels that they found the complete package with Swift-Cut.