C Madigan, a full line equipment distribution & installation operation based in Lancaster, Massachusetts, supplies dump bodies, lift gates, and snow-removal equipment to municipalities and commercial fleets across New England. As demand grew, manual plasma cutting became a major bottleneck-slow, inconsistent, and labor-intensive. To enhance its market leadership, the company invested in the Swift-Cut XP Series CNCPlasma Table-making its first move into CNC automation and digital fabrication.

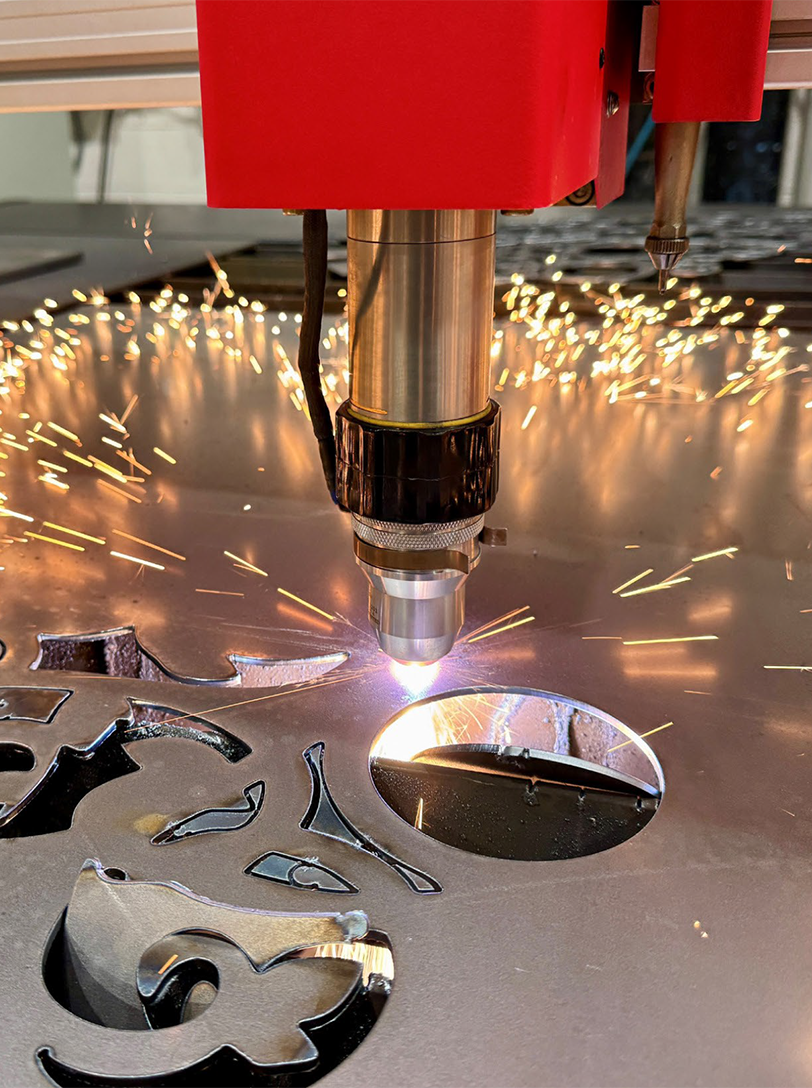

JC Madigan’s manual cutting process could no longer keep pace with production demands. Each part required multiple operations of cutting, grinding, and cleanup-adding time, cost, inconsistency and straining resources. The lack of repeatability made it difficult to maintain precision and finish quality.

Without upgrading to automation, JC Madigan risked operational inefficiencies and lack of product uniformity from its custom manufacturing operations which would hamper its ability to meet customers demands. To strengthen its leadership in the New England truck equipment market and support future growth, the company needed a more efficient and scalable cutting solution that could streamline fabrication, increase output, and eliminate rework without adding labour.

“The Swift-Cut XP has been a major boost to our productivity. As New England’s leading truck equipment distributor, municipalities and commercial fleets count on us to meet deadlines-and Swift-Cut make that happen.”

JC Madigan Team

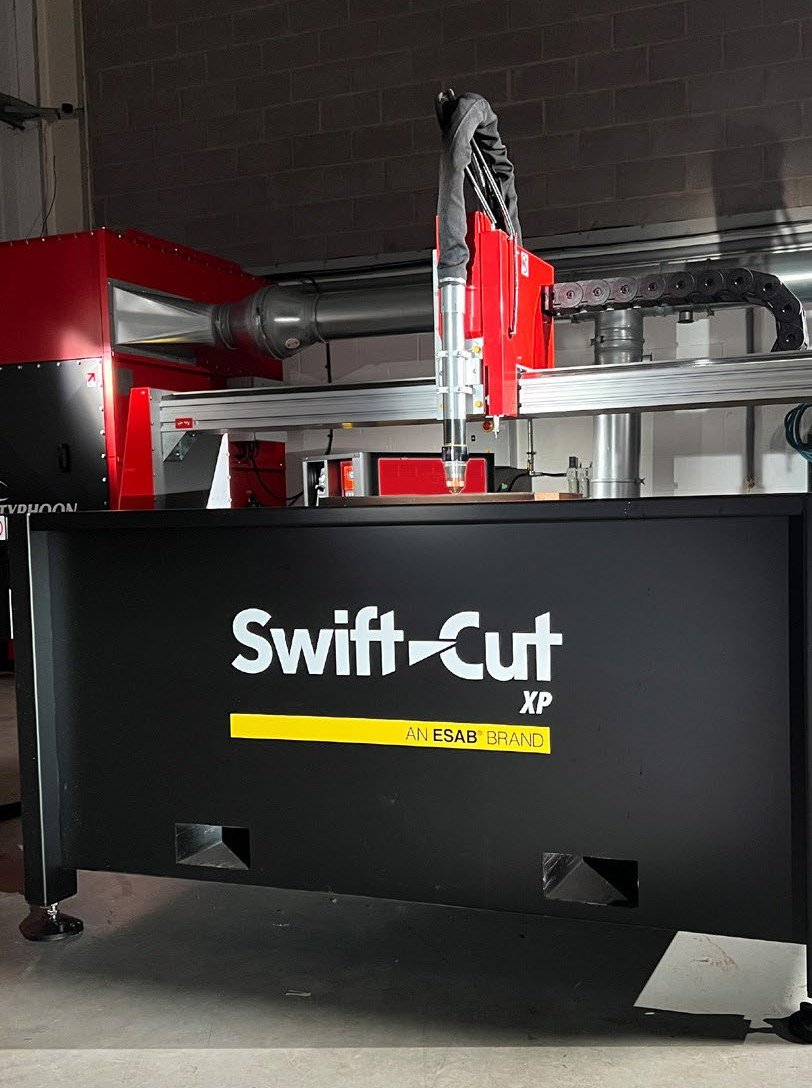

To address production bottlenecks, JC Madigan visited Swift-Cut’s headquarters in Plymouth, Massachusetts, for a live demonstration of the XP Series CNC Plasma Table using their part files. The machine’s speed, precision, and ease of use stood out immediately.

Impressed by its performance and intuitive design, JC Madigan invested in the Swift-Cut XP51 OWT CNC Plasma Table, the most advanced and productive model in the lineup. The Swift-Cut team provided on-site installation, setup, and operator training, ensuring a seamless transition from manual cutting to full CNC automation. With the deployment of automated cutting, operators began producing parts faster, cleaner, and with greater accurately from day one.

The integration of the Swift-Cut XP51 OWT CNC Plasma Table transformed JC Madigan’s fabrication operations-delivering major gains in speed, quality, and efficiency.

Key outcomes included:

- 90% reduction in custom manufacturing cycle times, significantly accelerating throughput.

- Major improvement in cut quality and precision, virtually eliminating rework and minimizing material waste.

- Smooth adoption by operators, leading to higher efficiency, accuracy,and confidence from day one.

- Minimal set up time between various materials and processes

This upgrade enabled JC Madigan to deliver higher output, superior quality, and faster turnaround, ensuring the company remains well-positioned to meet customer demand and sustain its leadership in New England’s truck equipment market.

Follow JC Madigan on Facebook