How important is air quality when it comes to CNC plasma cut quality?

Air quality should meet ISO8573-1 Class 1.2.2 (1 Particulate, 2 water, 2 oil) You need a constant pressure of 7.5 Bar (110psi ) Minimum of 17CFM compressor is needed for Swift-Cut tables Cut quality is a direct relation to air quality Air filters are recommended – such as our 3 stake air filter kit (5u, […]

Advantages and Disadvantages of a downdraft table vs a water table

Advantages and Disadvantages of a downdraft table versus a water table Downdraft Table advantages: Straight forward maintenance once set up with no water levels to check or refill Any fume created is drawn down and away from the operator, even when cutting material that isn’t positioned flat on the slats (i.e. box section, I beam [...]

Advantages and Disadvantages of a downdraft table versus a water table Downdraft Table advantages: Straight forward maintenance once set up with no water levels to check or refill Any fume created is drawn down and away from the operator, even when cutting material that isn’t positioned flat on the slats (i.e. box section, I beam [...] Hole tolerances

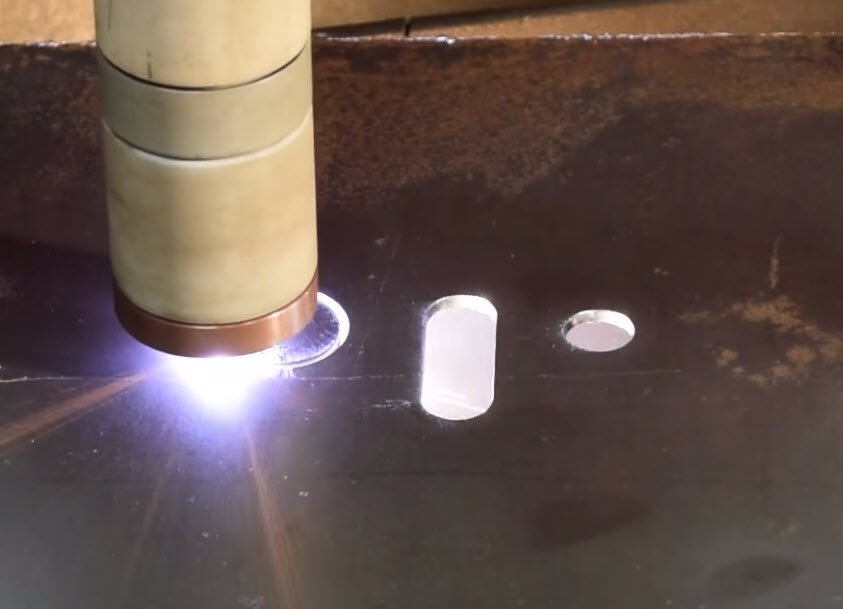

Hole tolerances It's a popular topic when discussing plasma cutting and one question we regularly get asked: What is the smallest hole size I can achieve using a Swift-Cut CNC plasma table? The simple answer, and the one we publish on our website is: Our machines follow the 2D rule. As such, when cutting a [...]

Hole tolerances It's a popular topic when discussing plasma cutting and one question we regularly get asked: What is the smallest hole size I can achieve using a Swift-Cut CNC plasma table? The simple answer, and the one we publish on our website is: Our machines follow the 2D rule. As such, when cutting a [...]