New Swift-Jet Pro has finally made water jet CNC cutting a reality for established company

It really is a case of ‘no job too small’ for Burton Rubber Co. Ltd, a company that specialises in providing bespoke rubber moulding and bondings into various industries including the industrial and automotive sector. Formed in 1968, the company now employs forty staff in their production plant in Burton-Upon-Trent, including in-house engineers for tool making and are both ISO:9001 and ISO:14001 quality approved.

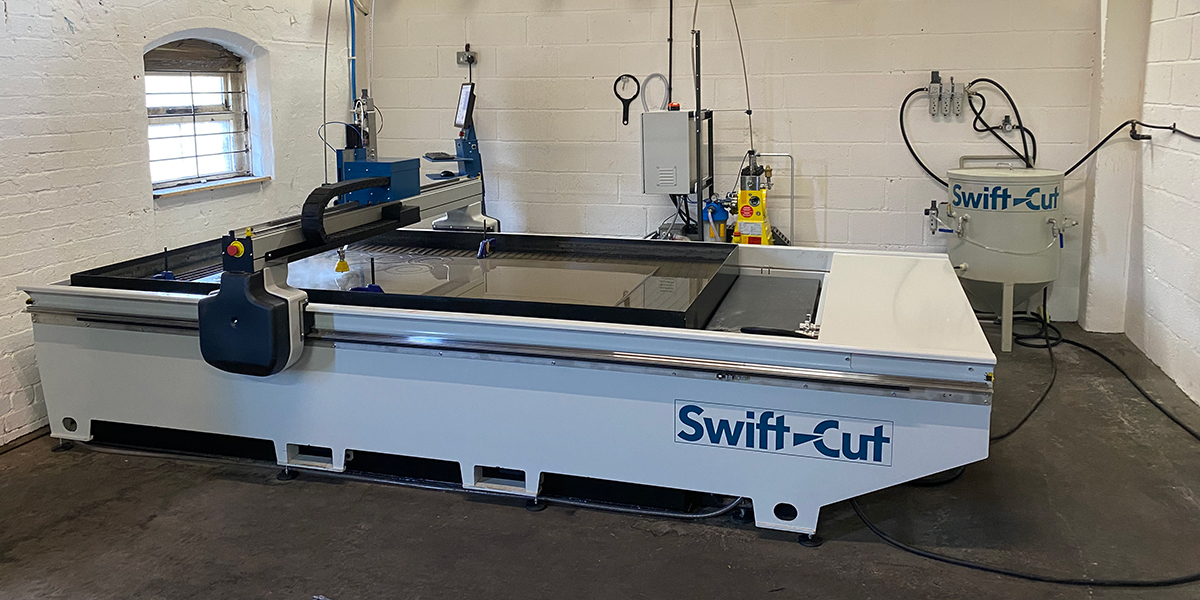

Their mission to supply quality products that meet each individual customer requirement has just been bolstered by the purchase of the Swift-Jet Pro, the new water jet CNC cutting machine from Swift-Cut.

Speaking to Charlie Insley, the Company Director, about their decision to venture into in-house water jet cutting, it’s clear that choosing Swift-Cut was not an overnight decision. In fact, Charlie has followed the Swift-Cut journey from its inception in 2011. He has watched the company grow, expand overseas and gain a huge industry following and it’s these aspects of the company, as well as his awareness of Swift-Cut ethos to provide the absolute best in quality and service which resonates so clearly in-line with Burton Rubber’s own mission, that cemented his decision to choose the Swift-Jet Pro 2500.

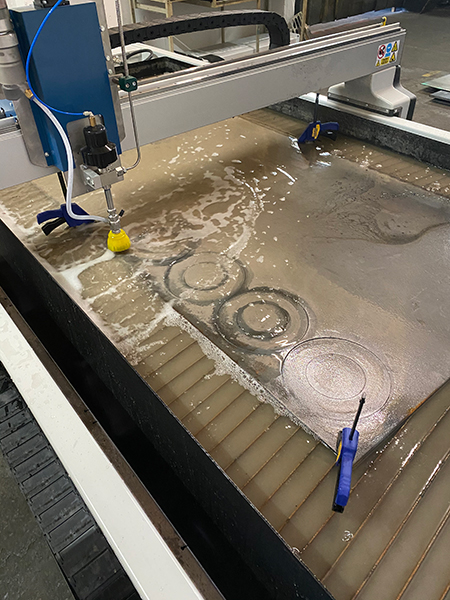

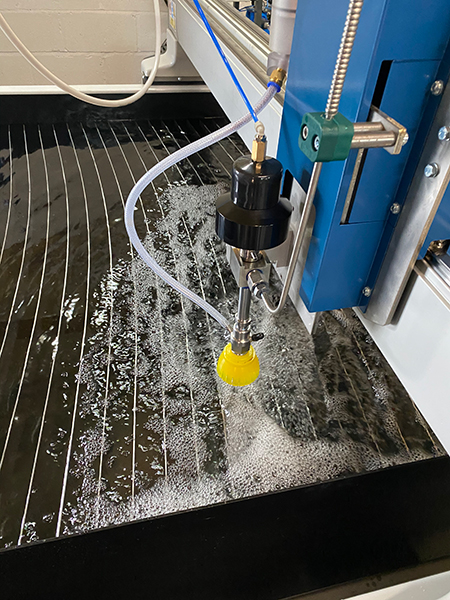

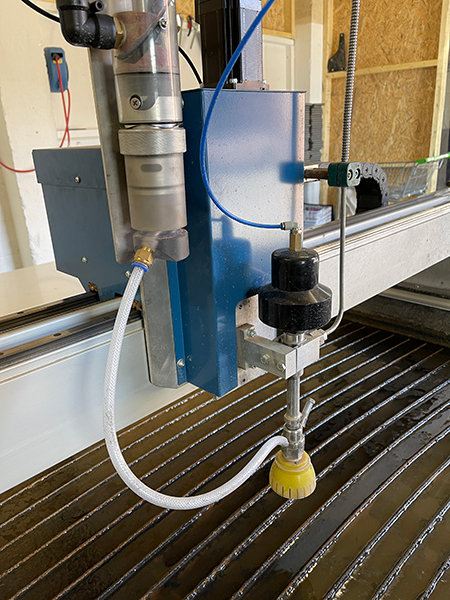

Predominantly purchased to cut reinforced rubber material (sheet), it will also cut mild steel up to 40mm and, as with so many of our customers, he is expecting to find a wealth of other purposes for it, some of which he is sure will only expand his output further.

Prior to taking ownership of their Swift-Jet Pro, Burton Rubber Co used a punch (cookie dough cutter) to produce rubber patterns in-house, and although this process is clean and fast, they had to outsource the thicker rubber parts as punching wasn’t suitable. Fortuitously, they were aware that their supplier used a water jet to produce the parts they were buying in, so they knew that the natural step was to investigate bringing manufacturing in-house with their own water jet, and so the conversation with Swift-Cut began.

Charlie had understood that water jet technology was over their budget, however with his knowledge of Swift-Cut, he knew that this was one machine he would be able to afford if they made it. And thanks to Swift-Cut designing and engineering a machine that is well below the industry price tag but as capable as any of the machines in the higher price bracket, he was immediately on board.

“Nothing else comes close in terms of price, features, and support!” Charlie Insley

Charlie reports that the Swift-Jet Pro stand out quality in terms of what it can do for Burton Rubber is its versatility – its ability to cut a wide variety of materials and manufacture parts and tooling for other areas of the business that they couldn’t before means less outsourcing. This in turn has enabled them to bring the price per part down dramatically, allowing them to remain competitive in what is currently a challenging economic environment. Add to that the variety of material types and thicknesses it can cut – it has really opened new opportunities for the business including a recent order they won, which relied on them having water jet technology at their disposal.

As part of their budgeting, using their current workload (the Swift-Jet Pro is currently only used a day or two a week) they have forecast that the machine will pay for itself within twenty-four months, which for such an incredible piece of machinery, is an impressive return on investment. But it doesn’t end there. With the ability to now accept and tender for new contracts that previously they would not have even considered, the return on investment is only going to get better, possibly smashing their twenty-four-month expectation.

It’s certainly going to be interesting to watch Burton Rubber Co as they embark on a new era for their business, enabled by the capabilities of the Swift-Jet Pro and their own skilled and passionate workforce.